Biomedical Engineering Reference

In-Depth Information

Table 6.1

Mechanical Properties Before and After a 75-kGy Gamma Irradiation Dose

Results Before

Sterilization

Results After

Sterilization

Test

Test Method

Tensile strength

ISO 527

100.69 MPa

99.77 MPa

Tensile elongation

ISO 527

32.21%

34.30%

Flexural strength

ISI 178

163.88 MPa

163.73 MPa

Flexural modulus

ISO 178

3.99 GPa

4.09 GPa

7.0 kJ/m

2

7.3 kJ/m

2

Impact strength (Notched Izod)

ISO 180

Density

ASTM D792

1.30 g/cc

1.30 g/cc

T

g

(onset)

DSC

146.77

C

144.33

C

Melt temperature

DSC

341.30

C

339.49

C

Recrystallization temperature

DSC

289.77

C

290.32

C

DSC, differential scanning calorimetry.

mobility of electrons along the molecular chain

[16]

.

In studies of free radical decay using electron spin

resonance(ESR),Lietal.

[16]

found no evidence of

residual free radicals in PEEK immediately after

exposure with up to 600 kGy of gamma radiation,

indicating that any free radicals produced by irradiation

of PEEK have a lifetime of less than 20 min, which

was the time needed to transfer the samples from the

irradiation chamber to the ESR instrument in their

experiment.

The radiation stability of crystalline and amor-

phous PEEK has been extensively studied for

the past two decades because of the interest in

spacecraft applications and nuclear fusion reactors,

where the total exposure to radiation ranges between

10 and 50 MGy (i.e., 10,000

e

50,000 kGy)

[2,15,

17

e

25]

. Although degradation and cross-linking of

PEEK occur at doses above 10 MGy, it should be

appreciated that the exposures of concern to the

aerospace and nuclear power industry exceed the

standard sterilization doses for medical devices

(25

e

40 kGy) by three orders of magnitude.

Table 6.1

demonstrates the mechanical properties of

PEEK-OPTIMA LT1 before and after a 75-kGy

gamma radiation dose.

Repeated sterilization, with up to four 25- to 40-

kGy doses of gamma radiation in air, has been

confirmed to result in no significant changes to the

mechanical behavior of PEEK and PEEK carbon

fiber composites

[6]

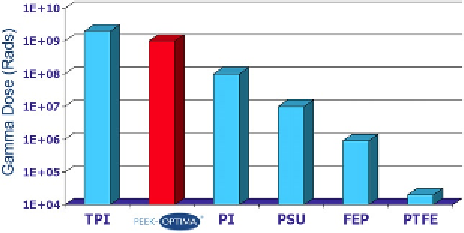

. This is demonstrated in

Fig. 6.2

,

which compares the oxidative gamma radiation dose

at which a slight (5%) deterioration of flexural

properties occurs in various polymers. Microstruc-

tural characterization of CFR-PEEK detected only

slight modification to the interphase region of the

composite, from 3 to 3.8

m

m in width, following

radiation sterilization

[5]

.

Therefore, reported radiation stability data indi-

cate that PEEK components may be effectively

sterilized by gamma irradiation in air. Although it is

possible to gamma sterilize PEEK components in

a low-oxygen environment, unlike UHMWPE, such

advanced packaging would not be expected to

confer improved shelf life. Test methods have been

Figure 6.2

The oxidative gamma radiation dose (Rads)

at which a slight (5%) deterioration of flexural proper-

ties occurs.