Biomedical Engineering Reference

In-Depth Information

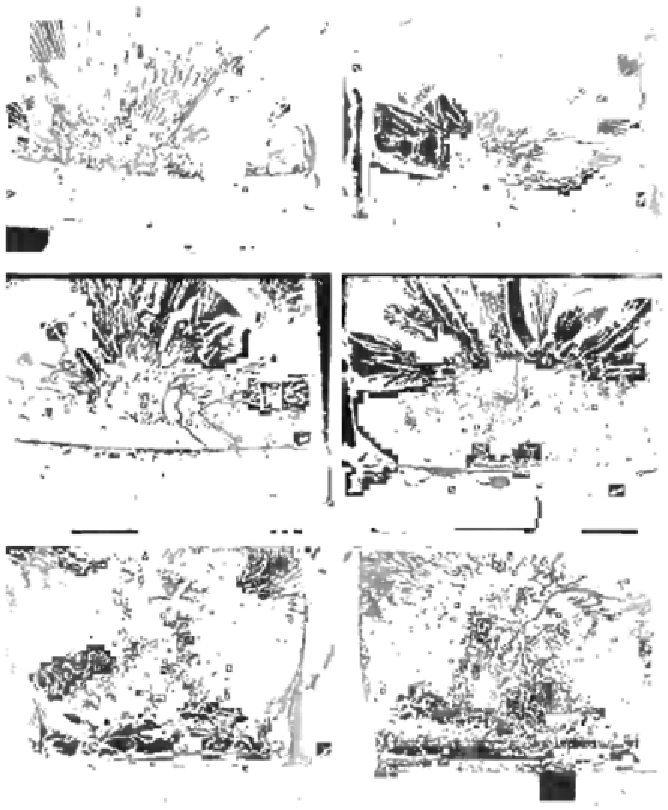

Figure 5.5

Fracture surface of

20% crystalline PEEK Charpy

impact specimens with different

notch radii. (a) Razor notch,

(b) 0.25 mm, (c) 0.5 mm,

(d) 1.0 mm, (e) 1.5 mm, and

(f) 2.0 mm. Courtesy of Ref.

[27]

.

(a)

(b)

(d)

(c)

(e)

(f)

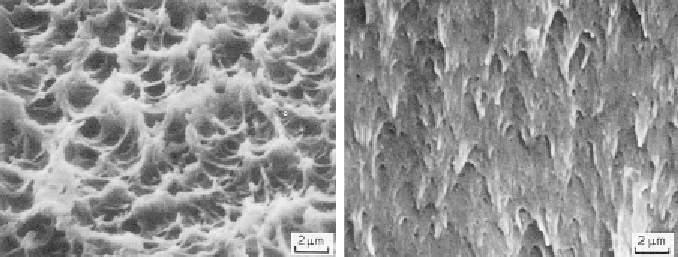

Figure 5.6

Scanning electron

micrographs of fracture surfaces

of PEEK CT specimens. Left:

PEEK 150P showing “nucleus

pull-out;” right: PEEK 450G

showing “hood-shaped” features.

Courtesy of Ref.

[29]

.

(

Fig. 5.11

). Also, we found that there was a dramatic

change in the fracture micromechanism of PEEK in

monotonic tension with notching. The primary frac-

ture mechanism of the smooth specimens involved

a specimen yielding and necking [which is a function

of Von Mises (VM) stress] followed by cavitation

(dependent on hydrostatic stress) then void coales-

cence, flaw formation, crack growth, and final frac-

ture (

Fig. 5.12

). All the notched specimens showed

three distinct zones: zone I showed evidence of