Biomedical Engineering Reference

In-Depth Information

significantly longer than an unnotched (smooth)

specimen with the same cyclic notch stress evenly

distributed across the entire cross-section. Because

of this observation, researchers have suggested

that failure is dictated by the stresses in a volume

of material in the vicinity of the notch root and not

just at the root itself

[24,25]

. Therefore, one cannot

simply adjust estimates of fatigue life by using

k

t

alone (even if the loading is primarily elastic); it

is necessary to test notched specimens in fatigue

to assess how the material will respond in

the presence of a notch under cyclic loading

conditions.

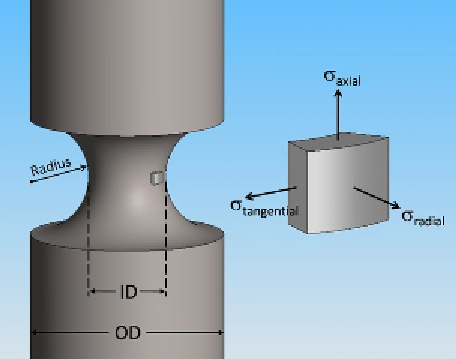

Figure 5.4

A cylindrical bar with a circumferential

groove. The enlarged element shows the directions of

the principal stresses generated at the notch under

an applied tensile load. Courtesy of Ref.

[43]

.

5.3 PEEK Fracture Studies

5.3.1 Mechanical Properties

As mentioned earlier, the minimum-notched Izod

fracture toughness for implantable PEEK is 4 kJ/m

2

[20]

. According to the material property data sheets

for Victrex PEEK, an increase in molecular weight

results in an increase in impact strength/toughness

[26]

. An increase in crystallinity has been shown to

decrease Charpy impact toughness

[27]

. Increased

aging of the polymer has been shown to decrease

Charpy toughness

[27]

, though it should be noted that

PEEK is relatively difficult to age in vivo. An increase

in the radius of curvature of the notch,

r

r

, of the impact

specimen increases the Charpy impact toughness

[27]

(

Tabl e 5 .1

).

This leads to an elevation in the apparent yield strength

of the bulk specimen, known as notch strengthening

[16]

. In a material that is notch sensitive (notch

weakening), the material has little plastic flow capa-

bility; fracture in the vicinity of the notch is initiated,

and the specimen fails primarily in a grossly brittle

manner.

Interestingly, the fatigue behavior of a notched

specimen is not necessarily determined only by the

cyclic stress at the notch (which is higher than

that experienced by the rest of the specimen). In

many materials, a notched specimen will survive

Table 5.1

Summary of Material and Testing Effects on Impact Toughness, Fracture Toughness

(

K

IC

), and FCG Resistance of PEEK

Effect on

Impact Toughness

Material/Testing Parameter

K

IC

FCG

Molecular weight

[

[

[

[

Percent crystallinity

[

Y

Y

[

Spherulite size

[

Y

Y

Aging

[

Y

[ r

r

[

Loading rate

[

Y

50 to 150

C)

Temperature (

(

J

IC

)

[

[