Biomedical Engineering Reference

In-Depth Information

polymers are less crystalline than polymers with

more flexible backbones, such as polyethylene (PE)

and polypropylene (PP), and more crystalline than

materials with bulky side groups, such as polystyrene

(PS). In several studies, the crystallinity, morphology,

and associated thermal behavior of PEEK have been

compared with polyethylene terephthalate (PET),

a linear aromatic polymer that is connected via ester

linkages

[4

e

6]

.

PEEK can be up to about 40% crystalline

[7]

,

though 30

e

35% is more typical. The result is a two-

phase morphology, consisting of crystalline regions

dispersed in amorphous polymer. The two-phase

model has been successfully applied to predict and

describe the density of PEEK

[4]

, though some

researchers have also described a rigid amorphous

phase exhibiting precrystalline ordering that is

intermediate between the disordered amorphous

condition and the ordered array characteristic of the

crystalline phase

[8]

.

Organization develops as PEEK chains align in

a symmetric repeating manner that is described by the

unit cell of the crystal. The chains fold and pack to

form lamellae, which grow into three-dimensional

spherulites. The number and size of the spherulites

depend on the nucleation and growth processes and

affect the physical properties of the material. Crystal-

lization behavior is tightly linked to processing

conditions (i.e., thermal history), and some researchers

have suggested that this includes the development of

both positive and negative birefringences in PEEK

crystallites

[4,9]

.

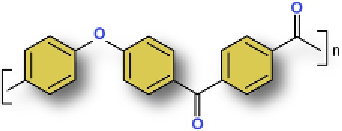

(a)

(b)

(c)

Figure 4.1

Schematic representation of polymer repeat

units for (a) PEEK, (b) PEK, (c) PEKK. Images courtesy of

Chris Espinosa, Exponent, Inc.

reported for PEEK and 34

for PEK

[3]

. Linkage

torsional angles can be affected by crystallization

temperature, with higher crystallization temperatures

resulting in more “twist” and less “stretch”

[3]

.

Large-scale structures are affected by the relative

polarity of the ether and ketone linkages and the twist

of the rings.

4.2.2 Morphology

PEEK and other PAEK polymers can be quenched

from the melt to form an amorphous, glassy solid. In

this state, the polymer chains adopt various confor-

mations that prevent efficient, regular packing, and

the material lacks long-range order. The amorphous

materials are generally transparent and exhibit lower

density than their crystalline counterparts. They also

lack the chemical resistance and mechanical prop-

erties that accompany the crystalline form. All

commercial polymers have some amorphous content

because polydispersity (i.e., a distribution of chain

lengths), the interconnected nature of the crystalliz-

able segments, and “defects” such as chain ends

prevent full crystallization.

Although it is possible to quench PAEK polymers

fast enough to create an amorphous, glassy material,

these polymers are readily crystallized either directly

during the manufacturing processes used to form

useful devices or during subsequent annealing

processes. Compared with other polymers, PAEK

4.2.3 Crystal Unit Cells

X-ray studies have confirmed that the unit cell of

PEEK is orthorhombic, exhibiting the symmetry of

space group Pcbn

[10]

. This unit cell and space group

applies to polyphenylene oxide (PPO), PEEK, and

PEK, which are linear aromatic polymers containing

100%, 66%, and 50% ether inter-ring linkages,

respectively. The unit cell of PEEK is depicted

schematically in

Fig. 4.2

. PEK also has an ortho-

rhombic unit cell

[2]

. In both PEEK and PEK, the

polymer backbone is aligned with the

c

-axis. The

structural repeating unit in crystals of the PAEK

polymers consists of two aryl rings. Chemically, the

repeating unit in PEEK contains three aryl rings,

which for symmetry expands to six aryl rings

[3]

. The

crystallographic pseudo repeat unit

is shown in

Fig. 4.3

.