Biomedical Engineering Reference

In-Depth Information

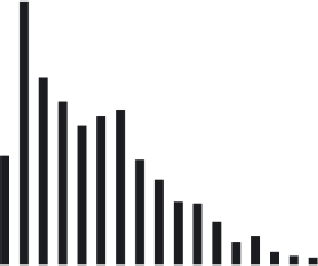

Figure 3.14

Fiber length distribution for

carbon fibers removed from injection-

molded short carbon fiber-reinforced

PEEK by acid digestion.

18

16

14

12

10

8

6

4

2

0

Fiber Length (microns)

For some implant devices, the strength and stiff-

ness of short CFR PEEK may not be sufficient to

resist the considerable biomechanical loads placed

on the material, yet the implant developer may wish

to retain the MRI and CT compatibility of a polymer

system and avoid the use of metals. In such cases it

may be necessary to change the configuration of the

fibers such that they are longer and more concen-

trated. This requires a different approach to their

incorporation and processing.

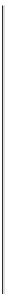

120

100

80

60

40

20

0

0

100

200

300

400

500

600

700

Fiber Length (microns)

Figure 3.15

Cumulative fiber length distribution for

carbon fibers removed from injection-molded short

carbon fiber-reinforced PEEK by acid digestion.

3.3.2 Continuous CFR PEEK

By “continuous” it is not meant that the fibers are

infinitely long, they are just long in relation to their

diameter. A reinforcing fiber may be considered

“continuous” when the mechanical properties no

longer respond to increases in fiber length. The precise

length at which this occurs depends on a number of

factors, including the relative strength or stiffness of

the fiber and matrix and the quality of the interface

between them. It may be regarded that continuous

means longer than about 6 mm, but more typically in

practical deployment, continuous fibers run the entire

length, or width, of the manufactured part.

The mechanical properties of continuous fiber

reinforced PEEK depend on the orientation of the

fibers in the classical way, as described by Hull and

Clyne

[8]

, with maximum tensile properties achieved

parallel to the fiber alignment direction. Woven

and unidirectional fiber pre-preg materials (pre-

impregnated with polymer) are possible with PEEK

and composite products can be manufactured by

stacking these pre-pregs in specific orientations rela-

tive to some reference axis that optimize the

mechanical strength or stiffness of the manufactured

250

200

150

100

50

0

Cortical

Bone

CF PEEK-

OPTIMA

Compound

PEEK-

OPTIMA

Polyethylene

Figure 3.16

Tensile strength of PEEK-OPTIMA and

short carbon fiber-reinforced PEEK-OPTIMA compared

with cortical bone and UHMWPE (polyethylene).

Source: Invibio.

that short CFR PEEK-OPTIMA has a stiffness that

more closelymatches the stiffness of bone. This “bone-

like” stiffness is an important attribute of CF PEEK-

OPTIMA materials

for

reasons

described

in

Section 3.1

.