Biomedical Engineering Reference

In-Depth Information

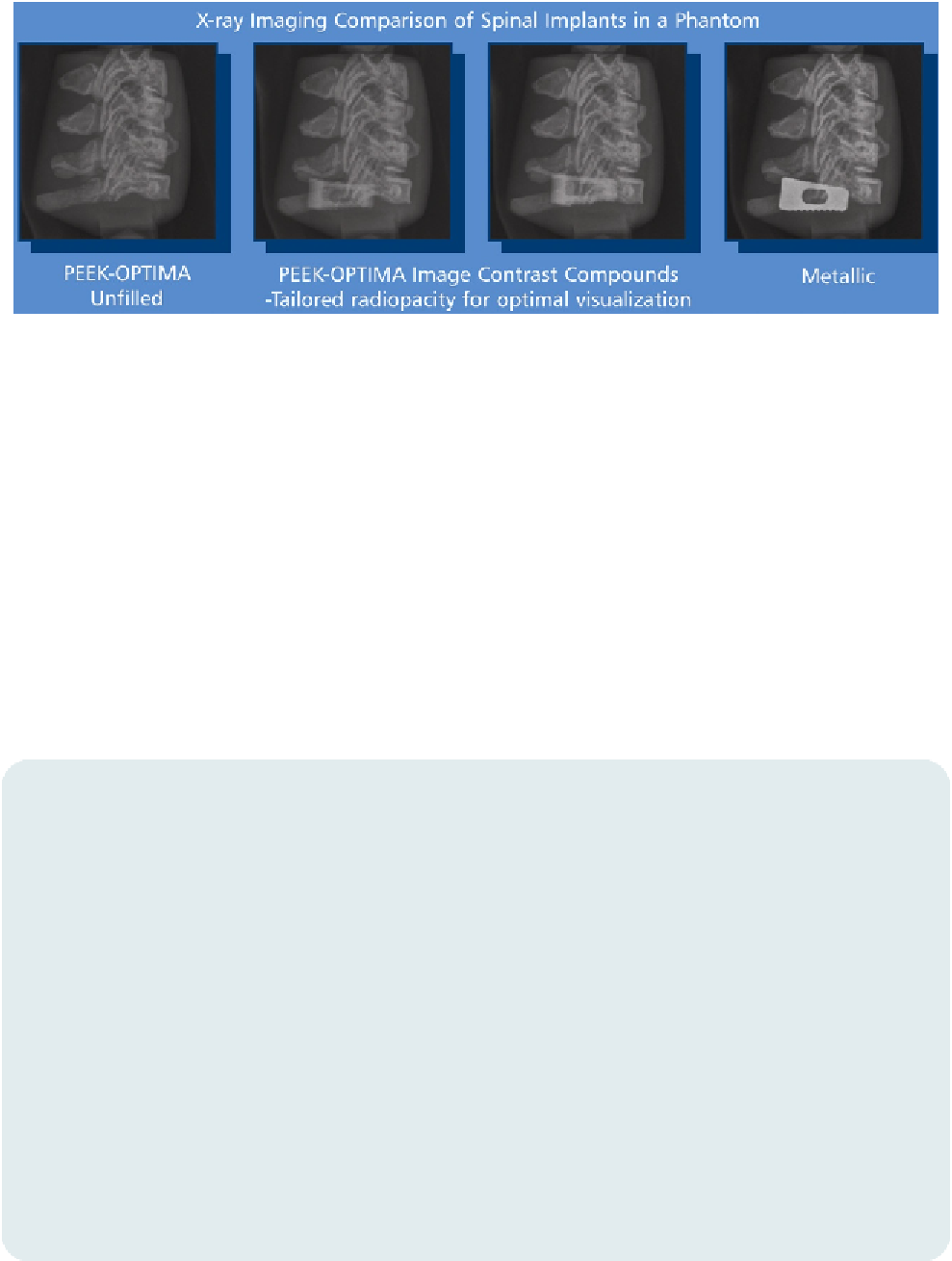

Figure 3.10

Spinal fusion cages made from PEEK-OPTIMA image contrast grades implanted in phantom. Photo

courtesy of Invibio.

compounds containing 4%, 6%, or 20% barium

sulfate, the implant developer can, therefore, tailor the

amount of radiopacity of the device to achieve an

optimized level of contrast. The radiographs shown in

Fig. 3.10

illustrate this for PEEK-OPTIMA polymer

spinal fusion cages that have been made with no

additive and 6% and 20% image contrast additive,

respectively, compared with a metallic cage.

Substantially, as a consequence of their shape,

powders do not enhance the tensile strength of polymer

materials compared with fiber reinforcements,

although there are physical changes to the base

polymer that occur as a result of their addition.

Tabl e 3 .2

compares the mechanical properties of

barium sulfate-filled PEEK with unfilled PEEK. It can

be seen that increasing the amount of filler actually

reduces the tensile strength of the material from 100

through 95 MPa, to 90 MPa with the highest filler

loading. This strength reduction is offset by the bene-

ficial gain in X-ray contrast, which, as has been illus-

trated, increases with increasing amounts of additive.

As an alternative method to adding radiopaque

powder, metallic wires (markers) may also be added

to PEEK (particularly to PEEK composites) to make

Table 3.2

Mechanical Properties of PEEK-OPTIMA Image Contrast Grades

PEEK-OPTIMA

Image Contrast Grade

(Low Radiopacity)

PEEK-OPTIMA

Image Contrast Grade

(High Radiopacity)

PEEK-OPTIMA

Unfilled

Property

Test Method Units

Tensile

strength

ISO 527

MPa

100

95

90

Tensile

elongation

ISO 527

%

20

20

15

Flexural

modulus

ISO 178

GPa

4

3.8

4.5

Flexural

strength

ISO 178

MPa

170

150

150

kJ/m

2

Notched Izod

impact

ISO 180

7.6

7

8

Specific

gravity

ISO 1183

g/cc

1.3

1.36

1.49