Biomedical Engineering Reference

In-Depth Information

implants that are extremely wear resistant can also be

made, and this is proving beneficial in the case of

some prosthetic hip designs.

Initially, the interest in CFR PEEK was largely

academic, but in the intervening years interest has

grown and the material is becoming a commercially

viable alternative to implant grade metallic alloys for

applications requiring high strength and fatigue

resistance. It is also being selected for the commer-

cial development of implantable load-bearing

medical devices, in which compatibility with modern

imaging technologies is a key concern, because

medical imaging is an important diagnostic tool and

it is desirable that the materials used in the

manufacturing of medical implants should be

compatible with a broad range of techniques.

In the case of X-rays, radiographically CFR PEEK

and natural unfilled PEEK polymers are transparent

(radiolucent), and this can be beneficial for a detailed

clinical inspection of the implant site. However, in

some cases it is necessary to have at least some level

of radiopacity, because the device may be required to

be observed using radiography for the medical team

to follow up on the clinical progress of the surgery.

Unfilled PEEK can be made moderately opaque by

the addition of a strongly X-ray absorbing filler at an

appropriate concentration, therefore called “image

contrast” grades. For this reason PEEK polymer has

been selected for the development of radiolucent

vertebral body replacement and other devices, which

enable the complete inspection of tissue and bone

growth via conventional imaging techniques.

Another benefit with medical devices that use

radiolucent materials is that they require less inten-

sive X-rays while retaining image accuracy and

definition; thus, overall patient exposure to radiation

is reduced.

Other medical imaging methods, such as computer

tomography (CT) and magnetic resonance imaging

(MRI), are not “metal friendly” and the presence of

metallic implants in the area being scanned can

significantly and negatively impact the quality of the

resulting images.

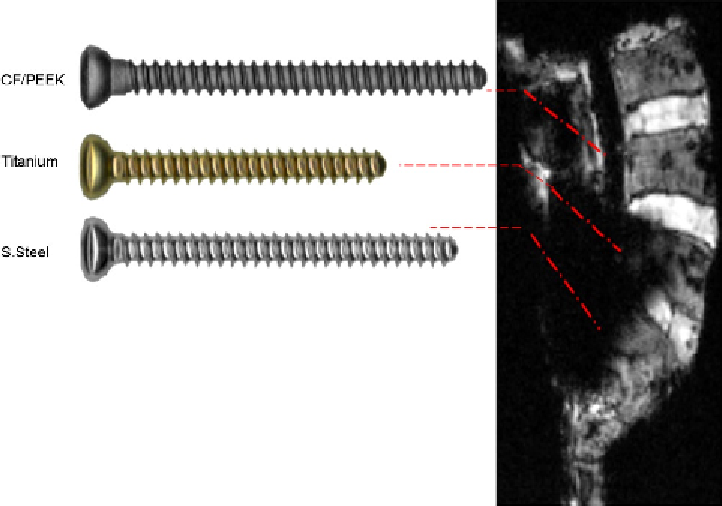

Figure 3.2

shows an example MRI

scan of a spine phantom with three implanted screws,

made from CFR PEEK, titanium, and stainless steel,

in upper, middle, and lower parts, respectively. It can

be seen that the image quality suffers significantly

from dark shadowing around the metallic implants,

whereas the image is significantly clearer adjacent to

the CFR PEEK screw.

In the case of CT images, metallic materials can

create artifacts where the signal from the directed

X-ray beam, required by the CT imager to reconstruct

the full

image, cannot penetrate the radiopaque

Figure 3.2

MRI image of CF/PEEK-OPTIMA, titanium, and stainless steel screws implanted in a phantom, illustrating

the dark shadowing that occurs around metallic implants. Photo courtesy of Icotec AG.