Biomedical Engineering Reference

In-Depth Information

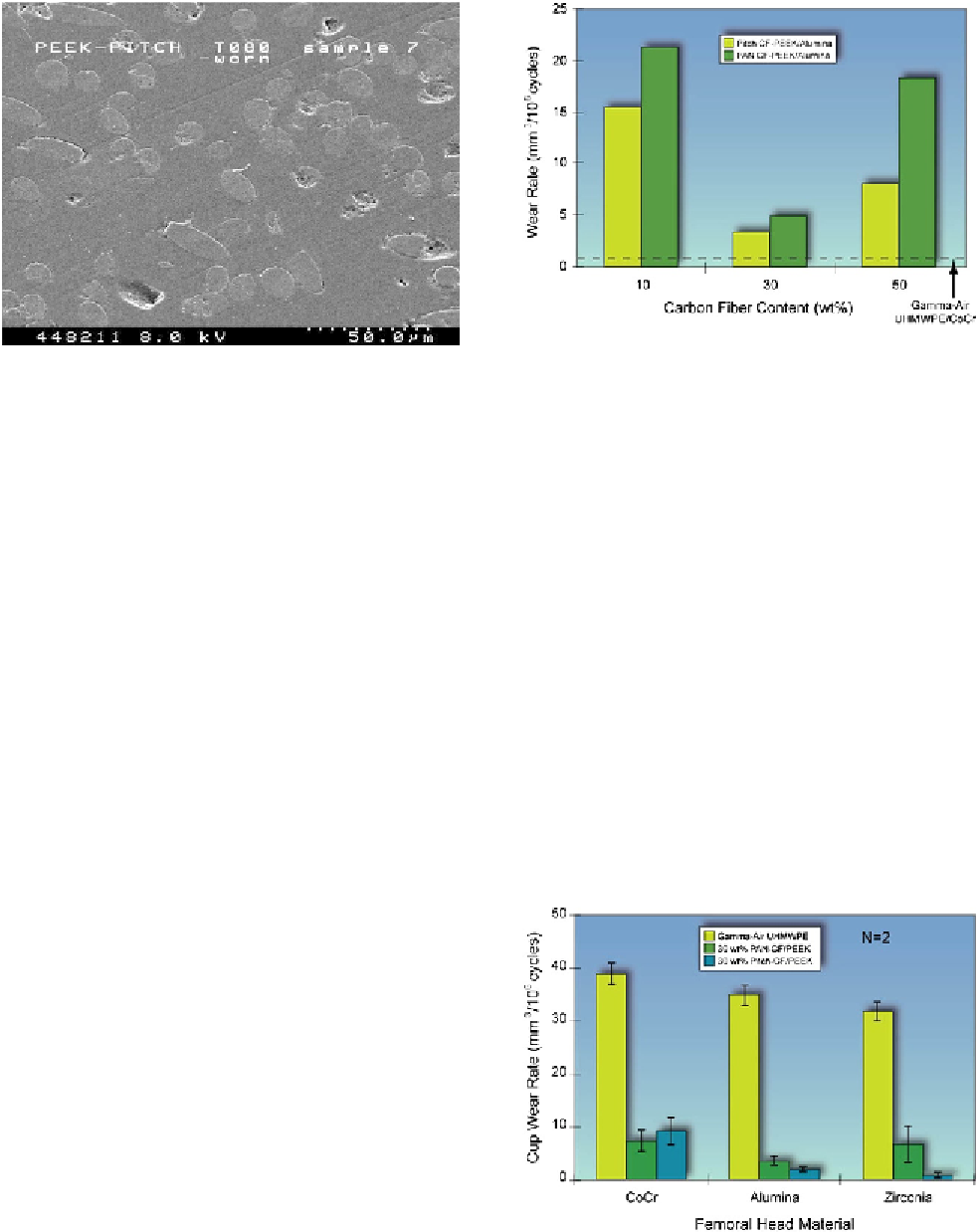

Figure 16.4

Wear performance of PEEK composites

and historical, gammaeair sterilized UHMWPE in

a cylinder-on-flat (knee-like) wear simulator. Adapted

from Ref.

[10]

.

Figure 16.3

Polished carbon fibers at the worn bearing

surface of invitro tested CFR-PEEK. The scanning elec-

tron microscopy image was provided courtesy of

Invibio.

a control. Under the higher stress, cylinder-on-flat

loading condition, the PEEK composites exhibited

higher wear

diameter and were tested in Vitallium (CoCr alloy)

metal shells. Gamma

e

air sterilized UHMWPE liners

(with a nominal dose of ~25 kGy) were evaluated as

controls. Zirconia heads (Prozyr: Desmarquest,

France) were used as the counterface. Five composite

cups and three controls were tested in an MTS hip

simulator to 10 million cycles, representing approx-

imately one decade of use for a typical elderly

patient. Bovine calf serum was used as the lubricant.

Under these conditions, the CFR-PEEK exhibited

two orders of magnitude less wear than the control

(0.39

rates

than the historical

control

(

Fig. 16.4

).

Under the lower stress hip simulator test condi-

tions, all the PEEK composites had substantially

lower wear rates than the historical control, with the

lowest wear observed between 30% pitch CFR-

PEEK against zirconia (

Fig. 16.5

). In contrast,

unreinforced PEEK wore at six times the rate of the

control UHMWPE.

The results of this study underscored the

importance of fiber reinforcement on lower stress,

conforming contact applications and provided

further basis for exploring the composite PEEK

5.4 mm

3

/million cycles, for

the composite and control, respectively). The authors

attributed the “exceptional” wear performance of

zirconia against CFR-PEEK in the hip simulator for

the effective load transfer and interfacial strength of

the PEEK and carbon fibers

[11]

.

Wang et al.

[10]

carried out a more comprehensive

tribological investigation of PEEK composites for

both hip and knee bearing applications. CFR-PEEK

formulations were injection molded using 150 G

resin blended with 20

e

30 w/w% discontinuous PAN

or pitch fibers. The polymers were tested against

CoCr alloy, zirconia, and alumina ceramic counter-

faces. The suitability for hip applications was tested

using the MTS hip simulator, whereas the suitability

for knee applications was evaluated using a multidi-

rectional cylinder-on-flat wear tester that resulted in

line contact conditions. Testing was performed up to

5 million cycles and with bovine calf serum as

lubricant. Once again, UHMWPE sterilized with

25 kGy of gamma radiation in air was used as

0.09 vs. 35.4

Figure 16.5

Wear performance of PEEK composites

and historical, gammaeair sterilized UHMWPE materials

in a hip simulator. Adapted from Ref.

[10]

.