Biomedical Engineering Reference

In-Depth Information

A general conclusion of the fracture healing and

stress shielding research is that desirable micro-

motion to enhance bone healing and maintain healthy

bone porosity is limited with the use of any rigid

metallic fixation. As discussed previously, from the

standpoint of fracture healing, it can be beneficial to

utilize semirigid internal fixation, allowing some

motion in specific directions. However, when

considering stress shielding, it seems more desirable

to fixate bone fractures with a material that is close in

mechanical stiffness to that of healthy bone.

Although exact requirements for rigidity are still

being sorted out, attempts have been made to estab-

lish some guidelines. For example, in the load-

bearing lower extremities, it has been recommended

to provide fixation of 43

e

53% that of stainless steel,

while in the forearm this percentage is approximately

30%

[10]

. What is certain is that a better under-

standing of how fractures heal and how bone main-

tains itself continues to support the concepts of

semirigid and biologic fixation. As we will see,

PEEK is an exciting option for application within

these two concepts.

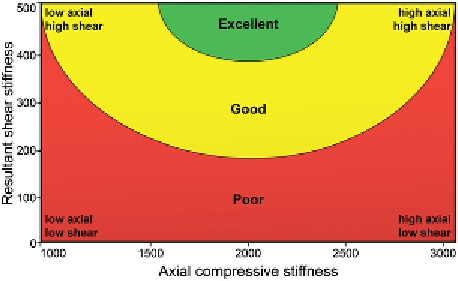

Figure 15.2

A plot of resultant shear stiffness vs. axial

compressive stiffness adapted from Epari et al.

[6]

. The

contours indicate areas of similar healing outcome and

describe the ideal healing environment as having

maximal shear stiffness and moderate axial compres-

sive stiffness.

plates for titanium, while others yet have decreased

the profile and bending stiffness of the implant

hardware. These have all been promising develop-

ments on the biologic fixation front, as the older

concepts of maximum mechanical stability had been

the primary design goal working against minimally

intrusive fixation. As we will see in the next section,

problems with overly stiff permanent hardware can

extend well past the initial healing period.

15.2.3 Semirigid Fracture

Fixation Plates

“Semirigid” carbon-fiber-reinforced (CFR) poly-

mer fracture fixation plates were developed starting

in the 1980s as an alternative to comparatively

“rigid” stainless steel bone plates

[11

e

16]

.As

a historical note, an investigation of CFR polymer

fracture fixation plates was reported by Bradley et al.

[16]

in the first published issue of Biomaterials.A

commercial epoxy prepreg resin was chosen as the

polymer matrix for the plates, and these implants

exhibited 1/3 of the bending stiffness and 10%

greater flexural strength than steel plates. The

biocompatibility of CFR epoxy plates was confirmed

to be comparable with stainless steel plates by testing

biopsy samples from tissue obtained when the

devices were surgically removed following fracture

healing

[17]

. However, an important disadvantage of

a thermosetting polymer, such as epoxy, is its

inability to be contoured to the bone fragments of

a fracture, rendering it less clinically useful than

metallic or polymeric plates that have this capability.

High-performance thermoplastic materials,

including nylon 6-10, polybutylene terephthalate

(PBT), polysulfone (PS), and PEEK, were also

extensively studied as candidates for fracture fixation

15.2.2 Stress Shielding After

Fracture Healing

After a successful bone union with an internal

fixation treatment, the stiffness mismatch between

the fixation device and the bone can continue to cause

the implant to transmit the majority of stress. The

underlying bone will continue to adapt to its altered

mechanical environment. Wolff's Law dictates that

the density of bone is dependent on its stress condi-

tion

[7]

. If the applied stress environment of a load-

bearing bone region is decreased below its normal

physiological levels, the bone density of that region

can decrease leading to a reduction in strength, the

degree of which is directly related to the stiffness of

the implant material

[8,9]

. The effects of stress

shielding on a healed bone begin with the resorption

of bone on the endosteal cortex, followed by

a widening of the medullary canal and a thinning of

the cortices

[9]

. Clinically, stress shielding can

decrease local bone mineral mass and may lead to

either failure of the fixation or refracture of the bone

after plate removal

[3,8,10]

.