Biomedical Engineering Reference

In-Depth Information

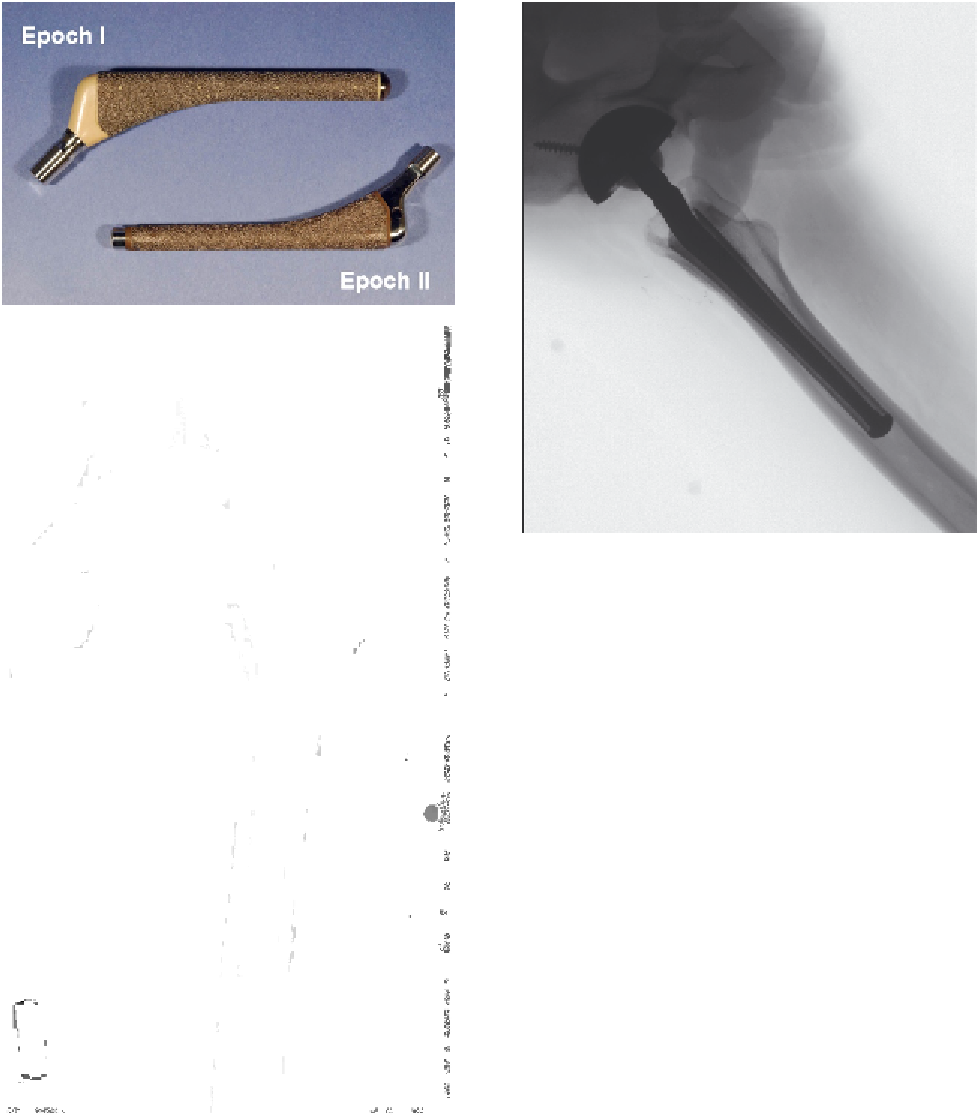

(a)

(c)

(b)

Figure 14.3

Continued.

considered by Zimmer, but engineers observed

polymer crazing of the composite hip stems upon

exposure to a simulated in vivo environment con-

taining lipids (

Fig. 14.5

). Challenges in material

selection, biocompatibility evaluation, and manu-

facturability were considered in parallel. Because

PAEK polymers were novel to orthopedics, a broad

range of biocompatibility tests were performed,

including cytotoxicity, carcinogenicity, acute

systemic toxicity, genotoxicity (ames mutagenicity),

genotoxicity (mouse lymphoma mutagenicity),

hemocompatibility, intracutaneous reactivity, mate-

rial-mediated pyrogenic response, and sensitization

[35]

. PAEK polymers did not exhibit an adverse

response when evaluated in this broad range of

biocompatibility tests.

The original Epoch stem (currently referred to as

“Epoch I”) was a three-part macrocomposite con-

sisting of a forged CoCr alloy inner core, an inter-

mediate layer of PEKEKK resin (UltraPek: BASF

Corporation), and outer bone ingrowth layer of

commercially pure Ti fiber mesh (

Fig. 14.6

).

A complex multistage manufacturing process had to

be developed for the Epoch stem. The CoCr core and

Ti fiber metal mesh were first fabricated and assem-

bled (

Fig. 14.7a

). The core/mesh assembly was

loaded into an injection-molding press, and molten

Figure 14.3

(a) First and second generations of the

Epoch hip stem (Zimmer, Warsaw IN). The Epoch I

stem was an anatomic design for left or right hips

and was fabricated from PEKEKK. The Epoch II design

is a straight stem and is fabricated from PEEK. (b) Ante-

rioreposterior radiograph of Epoch Stem at 10 years

follow-up. (c) Postoperative lateral radiograph of Epoch

stem.