Biomedical Engineering Reference

In-Depth Information

14.3 Setbacks with Early

PolymereMetal Composite Hip

Stems

The measured adoption of PEEK biomaterials in

hip stems has been tempered by previous experience

with the historical failures of isoelastic and Proplast-

coated hip prostheses in the 1970s and 1980s, and,

most recently, isoelastic polysulfone composite stems

in the 1990s. The concept of a cementless “isoelastic”

hip stem was reportedly conceived in 1967 by Robert

Mathys as an alternative to the cemented metallic hip

implant design developed by Sir John Charnley

[4,5]

.

The isoelastic hip stem was intended to replicate the

stiffness to the femur, to reduce stress shielding and

improve implant fixation. The first isoelastic hip

design, clinically implanted starting in 1973, was

a composite prosthesis consisting of a polyacetal

copolymer with a tapered metallic core (Factory for

Surgical Instrumentation, Bettlach, Switzerland). This

device was inserted without cement, and used a prox-

imal lag screw for fixation. Loosening of this pros-

thesis, attributed to poor clinical technique and

excessive proximal micromotion, also led to a second,

and ultimately a third generation of the RMI

Cementless Hip Prosthesis

[4,5]

. These subsequent

generations differed in geometric design, but retained

the same polyacetal copolymer fixation interface.

Despite encouraging short-term clinical results

[4,5]

,

longer investigation, with an average follow-up of 42

months, revealed unacceptably high rates of mechan-

ical loosening for the third-generation RMI prosthesis

[9]

. By 1988, Jakimet al.

[9]

noted that “the concept of

isoelasticity that has attracted many surgeons has

failed to fulfill original clinical expectations.”

Investigation of the retrieved periprosthetic tissues

from revision surgery patients demonstrated the

presence of polyacetal, polyethylene, and metal

particles. Extremely large foreign-body giant cells

were noted to be associated with polyacetal particles

[10]

. A later study confirmed that the adverse tissue

response was more intense for the polyacetal stems

than for CoCr stems

[11]

. The authors concluded that

increased stresses and micromotion at the proximal

calcar and the resulting generation of wear debris

(polyacetal and barium sulfate radiopacifier)

contributed to the poor long-term clinical perfor-

mance of the RMI stem. It is notable that the suit-

ability of polyacetal (Delrin) has been questioned for

orthopedic applications

[12,13]

.

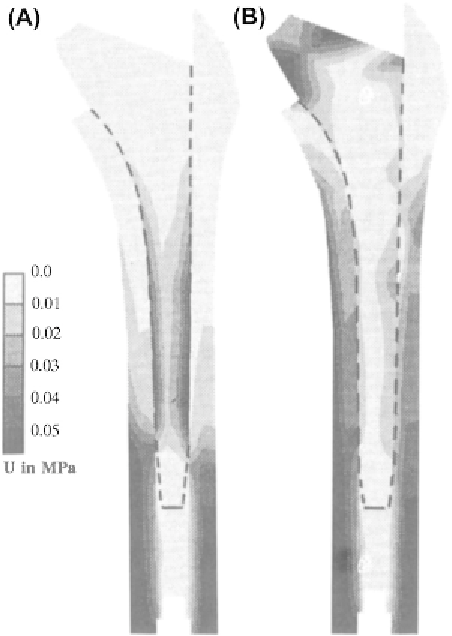

Figure 14.2

(A) Strain energy distribution in stem and

bone with CoCrMo prosthesis (a) and “isoelastic”

prosthesis (b). The average strain energy density from

three loading cases is shown. (B) Normal interface

stresses before and after simulated bone remodeling

for CoCrMo and “isoelastic” uncemented stems.

Images reproduced from Ph.D. thesis with permission

from Harrie Weinans, Ph.D.