Biomedical Engineering Reference

In-Depth Information

confer some subtle influence on cells

[31]

, so the

contrasting topography observed between porous and

machined samples may also influence the behavior of

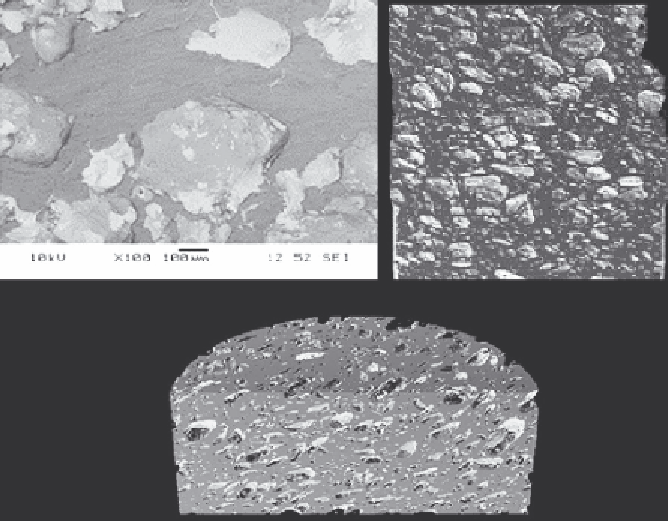

surrounding tissue. When assessed using scanning

electron microscopy (SEM) and computed tomog-

raphy (CT), the porous PEEK had a porosity of

approximately 50% and a mean pore size of 70

m

m

(

Fig. 12.3

). A 1 cm path of the surface was measured

using a surface roughness analyzer (Federal Prod-

ucts) at three locations parallel to the axis of the

implant. This confirmed that the porous PEEK

surface presented at the implant

e

bone interface is

rougher (

R

a

for intervertebral body fusion devices

. The results

showed an overall permanent deformation of around

25

m

m in compression after 5 million cycles over

6 days. Parameters were as follows: 10 Hz;

F

max

:

2.0 kN, corresponding to 10 N/mm

2

;

F

min

: 0.2 kN,

giving a load ratio of 10. Samples were 13

15

195 mm

2

.

4 mm “cervical” squares

¼

12.5.3 In Vitro Testing

Cell culture on this version of a porous PEEK-

OPTIMA has been previously reported by Tandy

et al.

[32]

. Cultures of marrow stromal cells were

seeded onto porous PEEK samples (7.25 mm in

width, 13.5 mm in length, and 4.25 mm in thickness).

After varying time points (7, 14, and 21 days), the

cultures were assessed for total DNA, alkaline

phosphatase, osteopontin, and calcium to indicate

stages of proliferation, differentiation and minerali-

zation, respectively. Researchers at the University of

Oklahoma observed that the production of extracel-

lular mineralized matrix by the cells on the porous

samples occurred within the study duration (21 days)

and was detected by calcium deposition assay.

Energy dispersive X-ray spectroscopy (EDS) anal-

ysis of the end study duration samples detected levels

of carbon, phosphorus, and calcium. The morphology

of the cells under SEM showed a polygonal cell

shape, which is

¼

6.5

m

m) than machined PEEK samples

(

R

a

¼

3.5

m

m).

12.5.2 Mechanical Testing

Mechanical properties of the porous material were

measured according to ISO test procedures (

n ¼

5)

and showed the following mean properties: ISO

527

d

tensile strength (porous 14.5 MPa, PEEK

105.5 MPa), ISO 180

d

strain at break (porous 3.5%,

PEEK 49.5%), impact strength (porous 3.6 kJ/m

2

,

PEEK 7.7 kJ/m

2

), ISO 178

d

flexural strength

(porous 21.6 MPa, PEEK 174.6 MPa), and flex

modulus (porous 0.8 GPa, PEEK 4.4 GPa).

Testing that was specifically relevant to a spinal

device was also performed, ASTMD695/ISO604 and

Dynamic fatigue test ASTM F2077-03

dTest method

typical of

the differentiated

Figure 12.3

Porosity of the porous

PEEK samples was evaluated

using SEM and micro-CT.

(a)

(b)

(c)