Biomedical Engineering Reference

In-Depth Information

O

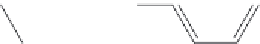

Scheme 2.2

O

O

C

OH

n

CF

3

SO

3

H

O

*

O

O

C

*

instability. When the reactive end group materials are

subjected to high-temperature processing, the poly-

mer immediately cross-links, producing gels, which

cannot be shaped into desired articles. Therefore,

PEEK production by electrophilic processes as

described earlier has historically had limited

commercial success.

More recently, a modification to the electrophilic

process for manufacturing PAEK polymers has been

described. This again involves the polycondensation

of 4-(4

0

-phenoxyphenoxybenzoic acid). However,

methanesulfonic acid was used as the reaction

solvent in the absence of phosphorus pentoxide, and

1,4

0

-diphenoxybenzene was used as an endcapping

agent

[8]

. This route permits the manufacture of

thermally stable PAEK polymers and has been used

in industrial processes (

Scheme 2.3

).

It should be noted that to ensure thermal stability,

significant quantities of the endcapping agent are

used and as a result may be present in significant

quantities in the finished polymer. The choice of the

endcapping agent may therefore significantly alter

the leachable and biocompatibility profile of the

material.

2.2.2 Nucleophilic Routes to PAEK

Polymers

The nucleophilic route to PAEK polymers

provides a straightforward pathway to polymers such

as PEEK. Initial attempts to form high-molecular-

weight PAEKs from the reaction of a dihalobenzo-

phenone and an equivalent bisphenate failed due to

the polymer product crystallizing from the sulfolane

solvent (

Scheme 2.4

).

Owing to the poor solubility of PEEK, the selec-

tion of the synthesis solvent is crucial. Suitable

solvents should be thermally stable and inert to

phenoxide species. It became apparent that solvents

such as benzophenone or diphenylsulfone could be

O

Scheme 2.3

O

C

OH

O

n

CH

3

SO

3

H

O

*

O

O

C

*

C

6

H

6

-O-C

6

H

6

End Capping Agent

O

O

C

O