Biomedical Engineering Reference

In-Depth Information

push-out

-TCP-reinforced PEEK

implants was 13% greater than that for PEEK alone

[24]

.

strength

of

b

(a)

25

human

cortical

bone (ll)

20

11.3.2 Functional Properties

A number of other functional properties are of

importance to bioactive PAEK composites. Dense

PAEK composites could conceivably be shaped

intraoperatively using a high-speed burr, whereas

porous PAEK composites could be shaped intra-

operatively using a scalpel or rongeur. The pore

architecture and interconnectivity of PAEK

composite scaffolds has been quantitatively charac-

terized using segmented micro-CT images

[28]

,but

there have been no experimental or computational

measurements of permeability to date. Calcium

phosphate reinforcement does not detract from the

advantageous radiolucency of PAEK, but may be

used instead of barium sulfate to tailor the radio-

pacity for visualization of an implant by X-ray

imaging. For example, PAEK reinforced with 40

e

50

vol%HA exhibits X-ray attenuation similar to human

cortical bone. Finally, just as the greater cost of

PAEK polymers over conventional biomedical ther-

moplastics (e.g., polyethylene) had to be justified by

enhanced performance, the added cost of raw mate-

rials and manufacturing bioactive PAEK composites

will have to be justified by additional performance

benefits in order to reach the market.

HA-PAEK

human

cortical

bone (

15

⊥

)

HA-oriented HDPE

HA-UHMWPE

10

5

HA-acrylics

HA-HDPE

HA-PLLA

0

0

10

20

30

40

50

60

Apatite Volume Fraction (%)

(b)

160

human

cortical

bone (ll)

HA-oriented HDPE

& HA-PLLA

140

HA-PAEK

120

human

cortical

bone (

100

⊥

)

80

60

HA-PMMA

40

HA-bis-GMA

20

HA-HDPE & UHMWPE

0

0

10

20

30

40

50

60

Apatite Volume Fraction (%)

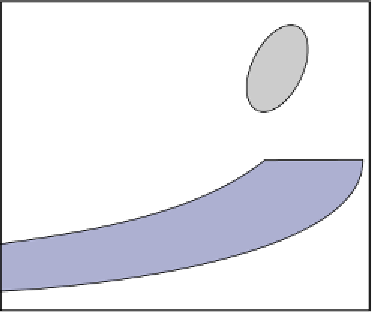

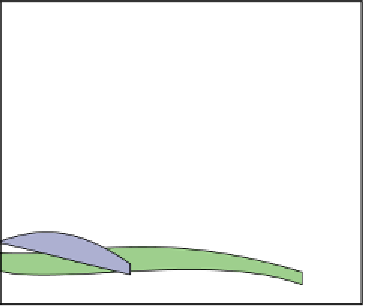

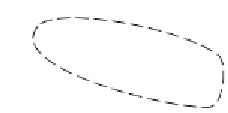

11.3.3 Mechanical Properties

The mechanical properties of bioactive PAEK

composites have been evaluated by static uniaxial

tension

[12

e

14,20,21,25]

, cyclic uniaxial tension

[14,15]

, static uniaxial compression

[20,29

e

31]

,

implant push-out strength

[24]

, ultrasonic wave

propagation

[25,26]

, static four-point bending

[32]

,

cyclic four-point bending

[27]

, static three-point

bending

[33]

, and micromechanical models

[26,74,75]

. PAEK composites have exhibited

excellent static mechanical properties and fatigue

properties compared with other polymers with

bioactive reinforcements (

Fig. 11.6

). Both dense and

porous PAEK composites have been engineered to

mimic mechanical properties exhibited by human

cortical and trabecular bone tissue,

Figure 11.6

The elastic modulus (a) and ultimate

tensile strength (b) of human cortical bone tissue

compared to polymers reinforced with varying amounts

of HA. The mechanical properties of cortical bone are

shown for loading parallel

)

to the longitudinal anatomic axis. Note that the regions

are shown to simplify and be inclusive of a large

number of data points from the literature for high-

density polyethylene (HDPE)

[6,8,76]

, PAEK

[13e15,21,25]

, ultrahigh-molecular-weight polyeth-

ylene (UHMWPE)

[77]

, acrylicsdincluding polymethyl

methacrylate (PMMA)

[78e80]

and bisphenol-

a

-glycidyl

methacrylate/triethylene glycol dimethacrylate (bis-

GMA /TEG-DMA)

[81e84]

dPLLA

[85,86]

, and aniso-

tropic (oriented) HDPE

[87e90]

. The dataset was

limited to uniaxial tensile tests in order to be free from

ambiguity due to variations in testing methods (e.g.,

bending tests).

(

k

) and perpendicular (

t

respectively

(

Table 11.3

).

Dense HA-reinforced PEEK was able to mimic the

longitudinal elastic modulus of human cortical bone

at a similar volume fraction of HA

[12

e

14,25]