Biomedical Engineering Reference

In-Depth Information

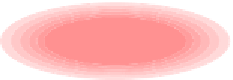

Figure 11.2

Schematic diagram showing a

more detailed description of processinge

structureeproperty relationships (

Fig.

11.1

) key to the design of calcium

phosphate-reinforced PEEK composites

for biomedical devices.

DEVICE PERFORMANCE

PROCESSING

PROPERTIES

BIOLOGICAL

• biocompatibility

• bioactivity

• bioresorption

• osteoconductivity

• osteoinductivity

MATERIALS

PAEK

• polymerization

• compounding

• size fractioning

STRUCTURE

MOLECULAR (PAEK)

• composition

• molecular weight

• conformation

• configuration

• crystallinity

• orientation

CALCIUM

PHOSPHATE

REINFORCEMENTS

FUNCTIONAL

• formability

• permeability

• radiopacity

• cost

• availability

• solid state reaction

(high temperature)

• chemical solutions

(low temperature)

CRYSTALLINE

(calcium phosphate)

• stoichiometry

• composition

• size

• morphology

SHAPE FORMING

MECHANICAL

• elastic modulus

• tensile strength

• compressive strength

• fracture toughness

• fatigue life

• compression molding

• injection molding

• pressureless sintering

• selective laser sintering

• particle leaching

• machining

MICROSTRUCTURE

(composite)

• phase fractions

• porosity

• orientation

• gradation

opportunities to design and manufacture bioactive

composites with tailored properties (

Fig. 11.2

).

(OXPEKK-C), has also been investigated

[27

e

30]

.

PEEK products are also currently available from

Evonik Industries (VESTAKEEP

) and Solvay

Advanced Polymers (KetaSpire

and Zeniva

)but

have not yet been used in published reports for

bioactive composites. The crystallinity of all the

above products is generally in the range of 30

e

35%

as-received. The crystallinity after molding will be

discussed further in Section

11.2.3

.

11.2 ProcessingeStructure

Relationships

11.2.1 PAEK Synthesis and

Structure

The processing of PAEK beads and powders of

varying composition, molecular weight, size, and

crystallinity has been reviewed in detail in preceding

chapters of this topic and elsewhere

[3]

. Investigations

of bioactive PAEK composites to date have primarily

utilized commercial polyetheretherketone (PEEK)

beads and powders

[11

e

26,30

e

35]

manufactured by

Victrex (150XF, 150PF, and 450G), and their subsid-

iary Invibio Biomaterial Solutions under the trade

name PEEK-OPTIMA

(LT1PF and LT3UF) (

Table

11.1

). The 150 and LT3 grades have a number average

molecular weight (

11.2.2 Bioactive Reinforcement

Synthesis and Structure

Bioactive reinforcements or fillers have primarily

utilized crystalline calcium orthophosphates,

including stoichiometric HA

[11

e

20,34]

, calcium-

deficient HA

[25

e

31]

, and

b

-TCP

[21

e

24]

(

Table

11.1

). However, strontium-substituted HA

[32]

,

amorphous calcium silicate

[33]

, and Bioglass 45S5

[23,35]

have also been investigated. These and a wide

variety of other calcium phosphates are available for

use as bioactive reinforcements (

Table 11.2

). A key

aspect of selection is the solubility of a particular

composition or stoichiometry, which influences bio-

logical properties and will be discussed further in

Section

11.3.1

.

High-temperature synthesis

d

including solid-state

reactions, molten salt synthesis, and spray drying with

calcination

d

generally leads to stoichiometric phases

M

n

) of 83,000, while the 450 and

LT1 grades have a number average molecular weight

of 115,000. Powder grade PF, XF, and UF have a mass

average particle diameter (

D

50

) of 50, 25, and 10

m

m,

respectively. A polyetherketoneketone

(PEKK)

powder with a mean particle size of 70

m

m, manu-

factured

by Oxford

Performance Materials