Biomedical Engineering Reference

In-Depth Information

detached from the substrate. The adhesion is almost

exclusively due to mechanical interlocking between

coating and substrate and the interface is the weakest

region, although some coatings are porous.

Hydroxyapatite is more brittle than titanium and

tends to leave more residuals on the substrate surface.

As discussed in Section

9.5

, several chemical

analyses can be performed on the hydroxyapatite

coating to determine crystallinity and presence of

metallic elements. Analyses on scraped powder from

HA coatings gave the information summarized in

Table 9.4

and

Fig. 9.18

, confirming the capability to

keep HA coating composition in compliance with

standard requirements.

9.7.2 Substrates Characterization

Important information can be gathered from

chemical analyses such as FT-IR and DSC. As an

example,

Fig. 9.19

shows two absorbance spectra of

a Motis

substrate before and after plasma spray Ti

coating. The two spectra exhibit similar absorbance

curves and peak heights. Keeping in mind that the

effects of UV degradation are evidenced by typical

bands such as those shown in

Fig. 9.10

, the absence

of peaks around 1730 cm

1

and in the region

3100

e

3700 cm

1

confirms that the material did not

undergo chemical degradation. The intensity of the

peak at 1215 cm

1

remains unchanged in relation to

the nearby peaks too, which means that the amount of

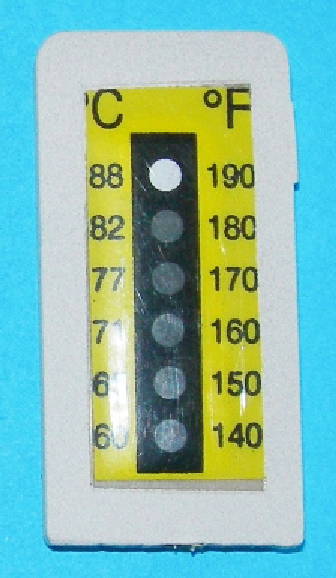

Figure 9.13

The temperature-indicating strips were

placed on the surface of a plate made of unfilled

PEEK before starting the plasma spray HA coating

process. A second thin film was placed over the strip,

which could be detached after treatment, to remove

the coating and uncover the strip. The HA coating is

therefore present only on the outer border of the

plate.

Table 9.3

Typical Characteristics of the Coatings Developed for PEEK-Based Substrates

Average

Roughness,

R

a

(

Recommended

Thickness (

Tensile Adhesion

Strength (MPa)

Coating

Porosity (%)

Substrate Coating

m)

m)

m

m

Optima

LT1

Ti, low roughness

100

50

8

1

28

4

3e10

Hydroxyapatite

65

20

6

1

19

3

10

<

Optima

LT1CA30

Ti, low roughness

100

50

7

1

32

7

3e10

Ti, high roughness

300

100

16

1

25

2

20e40

Hydroxyapatite

65

20

7

1

22

5

10

<

Endolign

Ti, high roughness

80

20

14

2

36

7

20e40

Motis

Ti, low roughness

100

50

7

1

33

3

3e10

Ti, high roughness

200

50

20

2

34

4

20e40

The recommended thickness is intended as the maximum peak height of the coating.