Biomedical Engineering Reference

In-Depth Information

on the test method as long as some geometrical

conditions are preserved.

The same type of specimen can be used for

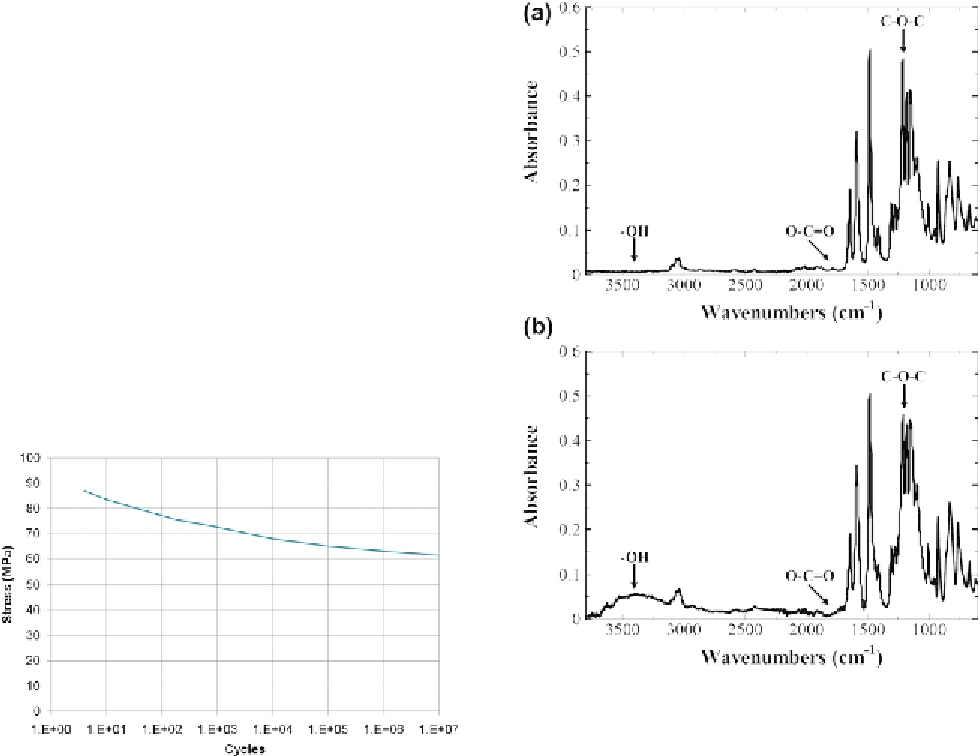

determining the fatigue strength, thus subjecting the

material to cycling loading conditions and counting

the number of cycles to fracture. By repeating the test

at various loading levels, a fatigue curve can be

obtained and plotted on a graph, such as in

Fig. 9.9

.

The load level at which the material sustains the

cycling loading without rupture, or at which failure

occurs at an elevated number of cycles (e.g., 10

7

cycles), is defined as fatigue strength or fatigue limit.

The fatigue curve is affected by parameters such as

wave form, frequency, minimum and maximum

applied load, and specimen geometry, and it is

therefore not only material related but also method

dependent. Care must be taken when comparing

fatigue

material may indicate the presence of impurities or

a chemical modification of the original chemical

structure. In the case of PEEK, the FT-IR technique

can be used to verify the absence of thermal or

photodegradation.

Figure 9.10

shows the differences

in the IR-absorbance spectra of a PEEK sample

before and after exposure to UV irradiation

[78]

.

X-ray photoelectron spectroscopy (XPS, also

known as ESCA, an abbreviation for electron spec-

troscopy for chemical analysis) is a chemical analysis

technique that measures the elemental composition,

empirical formula, chemical state, and electronic

state of the elements present on the surface. A typical

XPS spectrum is a plot of the number of electrons

detected (sometimes per unit time) versus the binding

energy of the electrons detected.

values

generated

in

different

testing

conditions.

Mechanical strength and fatigue resistance can be

determined also in a flexural testing configuration, as

described, for example, in ISO 178 or in ASTMD790

[75,76]

. Rectangular samples are used in this case,

and the most commonly used size is 10 mm

4mm

80 mm for ISO and 3.2 mm

12.7 mm

125 mm

(0.125

00

5.0

00

) for ASTM.

Fourier transform infrared spectroscopy (FT-IR) is

used to obtain an infrared spectrum of absorption of

a solid, liquid, or gas

[77]

. A typical FT-IR spectrum

is a plot of the intensities of the absorbed or trans-

mitted light versus its wavenumber. The infrared

spectrum is characteristic of the molecular repeating

units, and the presence of additional bands in the

infrared spectrum compared with the reference

0.5

00

Figure 9.10

FT-IR spectra of PEEK sample before (a)

and after (b) exposure to UV irradiation. UV photons

react with the aromatic ether bond (decrease of

CeOeC peak around 1215 cm

1

), and form eOH and

OeC]O groups (increase of absorbance in the region

3100e3700 cm

1

Figure 9.9

Tensile fatigue curve for PEEK Optima

LT1

at 23

C. Adapted from PEEK Optima

Data Sheet,

Invibio Ltd.

and around 1730 cm

1

). Adapted

from Ref.

[78]

.