Biomedical Engineering Reference

In-Depth Information

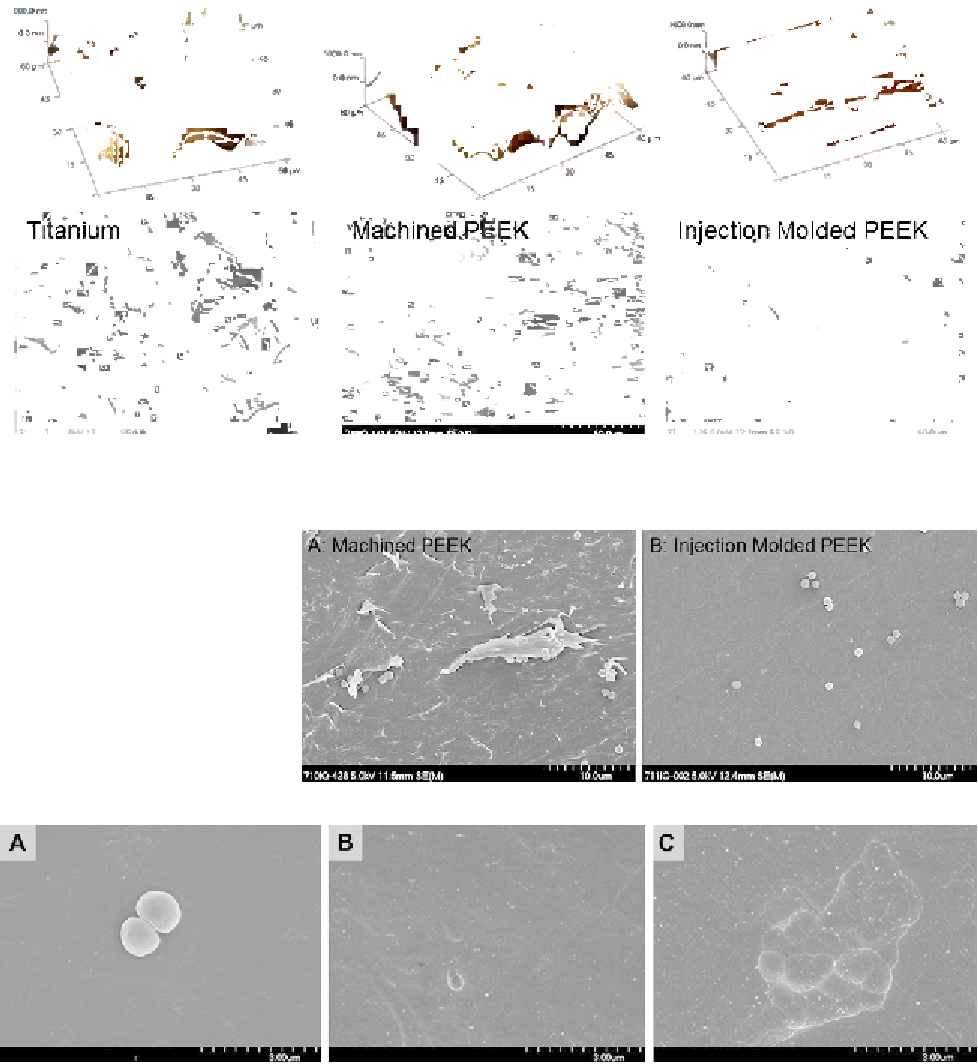

Figure 8.6

Atomic Force (top) and SE (bottom) micrographs of typical examples of commercially pure titanium,

machined PEEK, and injection-molded PEEK biomaterial surfaces.

Figure 8.7

SE micrographs

of adherent

S

.

aureus

, the ~1-

m

m-diameter spheres, on (A)

machined PEEK and (B) injection-

molded PEEK surfaces.

Figure 8.8

(A) Untreated injection-molded PEEK topography with two adherent

S

.

aureus

for scale. Exposure to

oxygen plasma results in the etching of a nanotopography and some pitting after 15 min (B) and extensive etching

and pitting after 15e30 min (C).

Section

8.3.2

). Prolonged exposure to oxygen plasma

can lead to etching of the polymer surface, creating

a topography consisting of recesses and peaks. Due to

the semicrystalline nature of PEEK, recesses form

more readily in amorphous areas susceptible to

etching while peaks form in regions of crystalline

polymer more resistant to the effects of plasma

exposure

[84]

. However, work from our laboratory

shows that the increase in nanoscale roughness

produced by plasma

etching injection-molded