Biomedical Engineering Reference

In-Depth Information

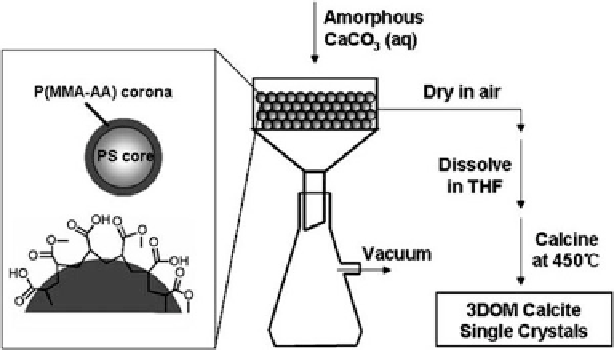

Fig. 6.11

Fabrication of 3DOM calcite single crystals by templating colloidal crystals of P(St-

MMA-AA) spheres carrying a carboxylate corona. (Reproduced from [

86

], Copyright © 2008,

Wiley)

well-defined 3DOM structure and controlled crystal orientation via specific surface

functionalization of the colloidal crystal template. Based on the experimental

results, they found that the calcite single crystals that formed in the colloidal crystal

template evolved form small patches to large symmetric dendrites up to several

tens of micrometers in size as the amount of ACC was enhanced. In particular,

two factors play key roles in the formation of the calcite single crystals, that is, the

vacuum-assisted filtration process which induces the filling of ACC in the interstices

of the template, and the surface-functionalized template which provided the affinity

to ACC [

86

]. In a typical experimental procedure, the 3D calcite single crystals were

achieved by infiltration of the ACC precursor into polymer colloidal crystals with

subsequent drying, dissolving in THF, and heated at 723 K as shown in Fig.

6.11

[

86

]. Monodisperse poly-(styrene-methyl methacrylate-acrylic acid) (P(St-MMA-

AA)) colloidal spheres, which have a polystyrene (PS) core and a carboxylate

corona [

87

], were assembled into 3D colloidal crystal on a filter membrane. Then,

a freshly obtained ACC dispersion was added dropwise to the colloidal crystal film

mounted under vacuum, leading to the deposition and crystallization of ACC within

the interstices of the colloidal crystals. These experimental results suggest a general

strategy for the design and fabrication of functional single-crystalline materials with

desired shapes, orientations, and nanopatterns.

Moreover, single crystals of calcite with regular patterned surfaces compris-

ing close-packed arrays of hemispherical cavities ordomes can be prepared by

crystallization on colloidal monolayers or polydimethylsiloxane replicas of these

monolayers, respectively [

88

]. This study demonstrates that crystallization within a

mould provides a general route to produce single crystals with unusual morpholo-

gies and curved surfaces.