Biomedical Engineering Reference

In-Depth Information

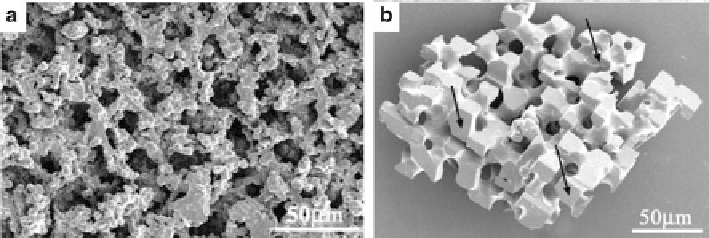

Fig. 6.10

Calcium carbonate precipitated in the polymer membrane. (

a

) Polycrystalline particle

precipitated from 0.4 M reagents, (

b

) templated single crystal of calcite precipitated from 0.02 M

solutions. (Reproduced from [

82

], Copyright © 2002, Wiley)

single crystals with complex form can be produced without using additives, by

external imposition of morphology (Fig.

6.10

). Calcium carbonate was obtained

in a polymer membrane, which had a same morphology to a sea urchin skeletal

plate. The polymer membrane was templated by a sea urchin plate and was

produced by dipping a plate in a polymer monomer solution, curing the polymer,

and finally dissolving away the calcium carbonate to obtain the polymer replica.

Precipitation of CaCO

3

in the membrane was received by placing the membrane

between two half U-tube arms, and filling them with Na

2

CO

3

and CaCl

2

solutions

respectively [

82

]. After a designated time, the membranes were removed from the

U-tube set-up, washed with water, and allowed to dry at room temperature for

1 day. Removal of the membrane by heating (at 773 K for 45 min) yielded the

particles of calcium carbonate that had been precipitated in the membrane [

82

]. The

experimental results demonstrate that the single crystals of calcite with sponge-like

morphologies were readily produced by precipitation within a suitable constrained

volume under controlled nucleation and growth conditions. They also investigated

the morphological control of single crystals by using the biological mechanisms

as inspiration [

84

]. Calcite was obtained within the cylindrical pores of track-etch

membranes via an ACC precursor.

Mosaic single-crystal CaCO

3

thin films can be obtained on modified

poly(ethylene terephthalate) (PET) templates [

85

]. The thin films can be fabricated

on chemically modified PET template surfaces by the process of transformation of

ACC film into a crystalline phase in air. The experimental results confirmed that

single-crystal CaCO

3

growth patterns are dependent on the surface characteristics

of the PET template. Therefore, the nucleation and growth of ceramic films on

polymeric templates can be controlled by chemical modification of the polymeric

template surface, and by subsequent attachment of ionic polyelectrolytes.

Qi et al. reported a novel approach to obtain three-dimensional ordered macrop-

orous (3DOM) calcite single crystals by combining the amorphous-to-crystalline

strategy with the use of colloidal crystals as 3D templates [

86

]. The results

demonstrated that that it is feasible for ACC to form single calcite with a