Biomedical Engineering Reference

In-Depth Information

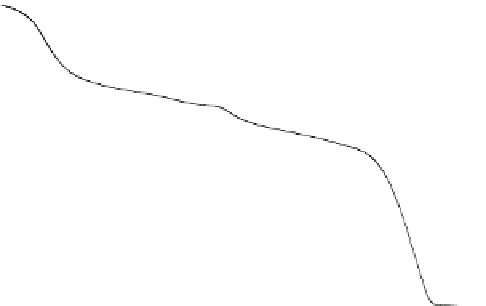

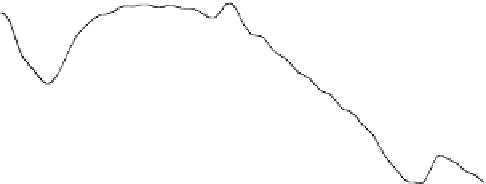

1.0

3

8%

0.9

0

13%

0.8

5

.

8

%

-3

0.7

-6

0.6

-9

32%

0.5

TG

DTA

-12

0.4

-15

100

200

300

400

500

600

700

800

Temperature (

o

C)

Fig. 6.3

Thermogravimetric and differential thermal curves of magnesium amorphous calcium

carbonate (Mg-ACC) powder. (Reproduced from [

53

], Copyright © 2010, Royal Society of

Chemistry)

The possible structure of the obtained Mg-ACC can be defined as Mg

0.15

Ca

0.85

CO

3

H

2

O

0.85

(Fig.

6.3

). The molar ratio of Mg

2C

:Ca

2C

:CO

3

2

and the concentration

(CaCl

2

,Na

2

CO

3

,andMgCl

2

) play important role in the Mg/Ca molar ratio of the

obtained Mg-ACC. In particular, the Mg-ACC can be preserved for over one year

without crystallization by either storing its dry powder at

5

ı

C or storing it in

ethanol at 5

ı

C. The access of Mg-ACC nanoparticles in large scale would be useful

for further biomineralization study and industry applications.

6.2.1.3

The Na

2

CO

3

-PAA-CaCl

2

Aqueous Reaction System

The nanosegregated amorphous composites consisting of CaCO

3

and an organic

polymer can be prepared by this method (Fig.

6.4

)[

54

]. The thin and bulk film

of the amorphous composites possessed stability and transparency. The amorphous

composite in the bulk state was formed by mixing the two solutions. The Na

2

CO

3

(0.1 M) solution was poured into the precursor solution containing polyacrylic

acid (PAA) (0.1 M) and CaCl

2

(0.1 M) at room temperature. A white precipitate

gradually appeared upon mixing of these solutions. The obtained product was

collected after 1-2 h by centrifugation and then the paste-like translucent material

was dried at room temperature. When the reaction took place without the PAA, the

ACC can also be obtained [

55

].