Biomedical Engineering Reference

In-Depth Information

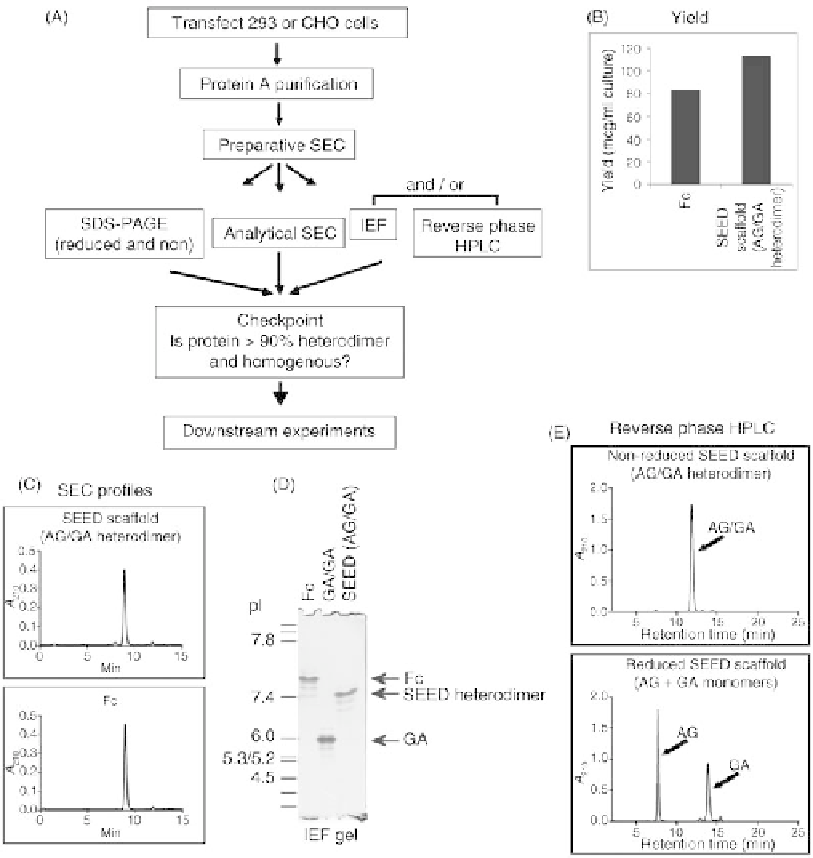

FIGURE 37.2

Expression, purification, and characterization of SEED proteins. (A) Standardized

workflow to produce SEED proteins by transient transfection, purify from medium, and determine if

the purified proteins pass the checkpoint for downstream experiments. SEC, size-exclusion chro-

matography; IEF, isoelectric focusing. (B) Example comparing yield after protein A purification of

IgG1 Fc and SEED. Yield measured as microgram protein A-purified protein per milliliter cell culture

medium. (C) Analytical SEC example comparing Fc and SEED scaffold proteins obtained after single-

step protein A purification. (D) IEF gel analysis example showing distinct focusing of Fc, SEED

heterodimer (AG/GA), and GA/GA homodimer. (E) Reverse phase HPLC example showing different

elution times of SEED scaffold (AG/GA heterodimer) compared to individual AG and GA chains.

molecular weight and percent aggregate of the purified

material was determined by SDS-PAGE (reduced and non-

reduced) and analytical SEC. Since SEED proteins should

be produced as heterodimers of the AG and GA SEED

chains, which have the same size, additional methods

were developed to measure AG/GA heterodimer proteins

versus homodimer and individual chains, specifically iso-

electric focusing (IEF) gel analysis and reverse phase HPLC

analysis. The workflow is designed so after

characterizations there is a checkpoint that requires that

the SEED proteins must be

90% heterodimer and homog-

enous before they can be used in further biophysical and

biological experiments. Proteins were routinely obtained as

>

>

95% homogenous AG/GA heterodimers.

In Figure 37.2, representative data sets are shown to

illustrate this workflow. For example, Fc- and SEED-based

proteins are produced with similar yields (

20-100

m

g/mL),

and in this example the yields of both Fc and SEED scaffold

these

Search WWH ::

Custom Search