Biomedical Engineering Reference

In-Depth Information

Broadband

light source

1x2

Coupler

2x2

Coupler

Isolator

PC

CND

G

DM

L

PC

M

D1

D2

Diff. amplifier

filter

demodulator

Probe

Sample

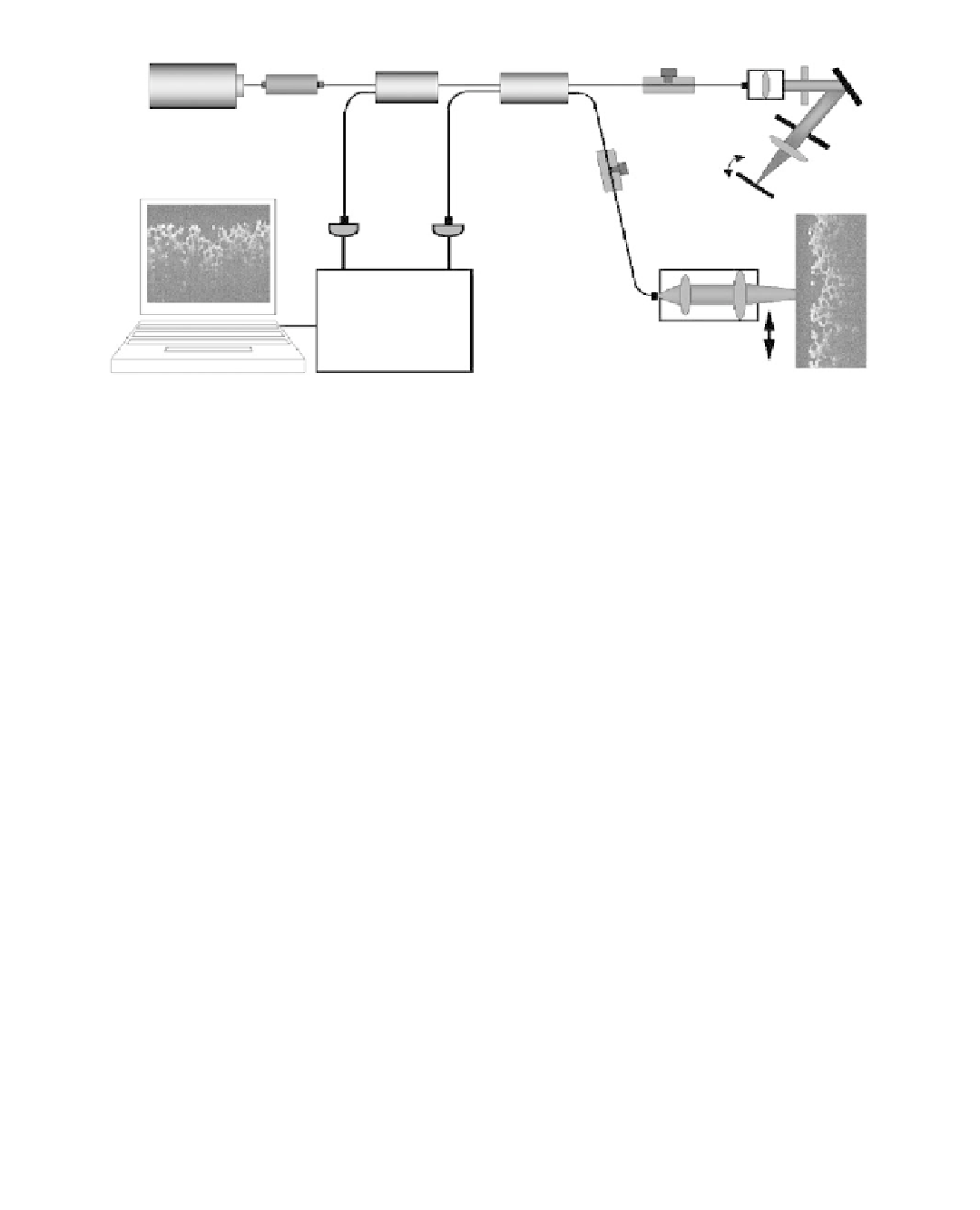

FIGURE 3.6

Schematic representation of OCT system setups used for the current investigations, where

PC denotes the polarization controller, C the collimator, ND the neutral density fi lter, G the grating, DM the

double pass mirror, L the optical lens, M the refl ecting mirror and D the detector.

145

The pore size in the PLLA scaffold made by single porogen was controlled between 255 and

350 µm, yielding a porosity of approximately 90% by the weight fraction of PLLA and salt in the scaf-

folds. When the salt crystal size is altered while maintaining the polymer/salt weight ratio, the resultant

scaffolds have different pore sizes but a similar porosity. Figure 3.7a gives an example of the resulting

OCT images from such scaffolds where an imaging depth of around 1 mm was achieved despite the

highly scattering nature of the scaffold. The top view image of the same scaffold from reconstruction

(Figure 3.7b) clearly presented the porous structure. The imaging contrast was primarily provided by

the difference in scattering coeffi cient among the polymer, PLLA, and PBS in which the measure-

ments were performed. The polymer backscattered the light, thereby appearing brighter, while the

pores appear as a dark area in the OCT image. Such contrast gives us an opportunity to estimate the

porosity from the OCT images. By using a commercial software, for example, Volocity, Improvision,

the porosity has been derived as 70%, which was close to the value estimated by stoichiometry.

Figure 3.8a shows the scaffold produced by dual porogen, NaCl and naphthalene, in comparison

with the same pore-size scaffold made by a single porogen, NaCl (Figure 3.8b). The corresponding

cross-section images are presented in Figure 3.9. Striking morphological changes can be seen when

compared with Figure 3.7a. First, the pore size in these scaffolds was smaller since 106-255 µm.

NaCl porogen was used in these scaffolds, demonstrating that OCT image can clearly distinguish

pore size variations in these scaffolds. Secondly, pore interconnection has been obviously increased

in the dual porogen-produced scaffolds. Introducing naphthalene as the second porogen in solvent-

casting and salt-leaching process resulted in the improvement of the pore interconnectivity. By

using 20% naphthalene, highly interconnected pore structures were achieved. This interconnection

feature has been further confi rmed by SEM analysis.

146

SEM images of the scaffolds prepared with

and without naphthalene are given in Figure 3.10. Extra-small pores presented in the pore wall were

visualized in the scaffolds produced with naphthalene. Figure 3.11 is a typical OCT image of porous

chitosan scaffolds with microchannels. The porous structure was clearly seen and the channels were

well-delimitated. The interconnected micropores have diameters ranging from 50 to 150 µm, while

the microchannels have a width of 250 µm. The typical image of the specimens shows a penetration

depth of more than 1 mm. On the other hand, the fi brous chitosan scaffolds exhibited a character-

ized morphology in OCT image. The diameter of the fi bers was very clearly delimitated, allowing

the examination of the distribution of the fi bers inside the scaffold (Figure 3.12).