Biomedical Engineering Reference

In-Depth Information

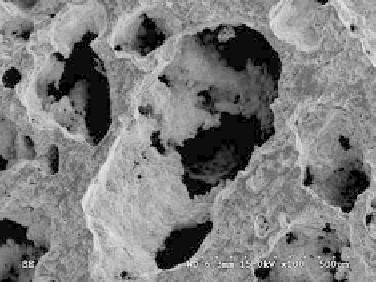

(a)

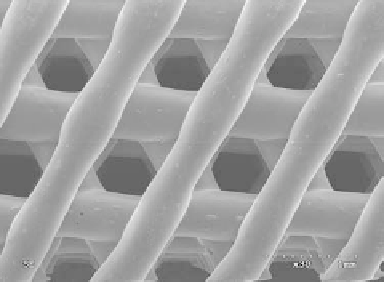

(b)

FIGURE 21.15

(a) Porous titanium scaffold made by powder sintering and (b) polymeric scaffold made

using fusion deposition modeling (FDM) by group of D. Hutmacher (National University of Singapore).

phenotypes. This is due to profi table mechanical proprieties, durability, elasticity, and the control-

led surface hydrophobicity of polyurethane scaffolds. In addition, the biodegradable polyurethanes

show a relatively low

in vitro

degradation rate, which follows a low rate of changes within the

chondral tissue [58]. Current research shows that 3D scaffolds prepared from linear, biodegradable

polyurethanes can be used as chondrocytes carrier [59]; however, this is not an ideal scaffold.

In the majority of the TE approaches, the above-mentioned materials were used to produce 3D

highly porous scaffolds for the cells. The high porosity is obtained by several methods, such as

freezing-thawing, salt or ice leaching, casting, foaming, sintering (Figure 21.15a), solid freeform

fabrication or rapid prototyping (Figure 21.15b), and fi ber bonding.

When the cartilage defect is accompanied by subchondral bone, the regeneration of the so-called

osteochondral defect requires the usage of a hybrid or biphasic scaffold, which has a specifi cally

designed cartilage compartment and a bone compartment [60]. Swieszkowski et al. [61] analyzed

two types of hybrid scaffolds: (i) the i rst biphasic scaffold consisting of i brin (cartilage phase) and

poly(ε-caprolactone) (PCL) (bone phase); (ii) the second type of scaffold using PCL as a cartilage

phase and PCL-TCP as a bone phase. The fusion deposition modeling (FDM) was used for scaffolds

fabrication (Figure 21.15b). The results of

in vivo

animal studies demonstrated that the porous PCL and

PCL-TCP scaffolds promoted bone healing. Integration of a regenerated cartilage with native one was

problematic. A better cartilage regeneration was obtained when the PCL scaffold has been used.

Application of PLGA microspheres in TE was also reported [62]. The characteristics of cartilage-

like tissue as a result of PLGA microspheres-chondrocyte arrangement showed to be very similar

in vitro

to properties of natural tissue, and they can fi nd applications in TE [62].

21.5 TOTAL JOINT REPLACEMENT

When AC is severely damaged because of a trauma or diseases such as osteoarthritis or rheumatoid

arthritis, the total joint replacement (TJR) is the most widely used treatment method.

TJRs are designed to mimic the anatomical joint structure and function as much as possi-

ble using available engineering techniques and materials. The affected and painful joint surfaces

are removed and replaced by two components, which restore the concave and convex geometry of

articulating surface of natural joint. The concave component material consists mainly of the ultra

high-molecular weight polyethylene (UHMWPE).

UHMWPE was classifi ed as a form of high-density polyethylene (HDPE) in the early 1960s [63].

It has been fabricated using the Ziegler process [64]. UHMWPE has a molecular weight ranging

between 3.1 and 5.67 g/mol million. For comparison, the molecular weight of HDPE is lower than