Biomedical Engineering Reference

In-Depth Information

OH

O

N

N

OH

H

NH

O

O

n

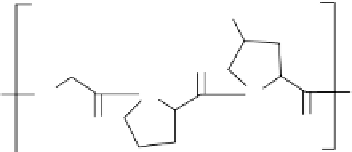

FIGURE 21.12

Chemical structure of collagen.

CH

OH

NH

2

NH

2

2

O

HO

HO

O

O

O

HO

O

n

N

H

2

CH

OH

CH

OH

2

2

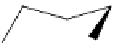

FIGURE 21.13

Chemical structure of chitosan.

O

CH

3

O

CH

C

CH

2

O

O

C

n

n

(a)

(b)

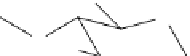

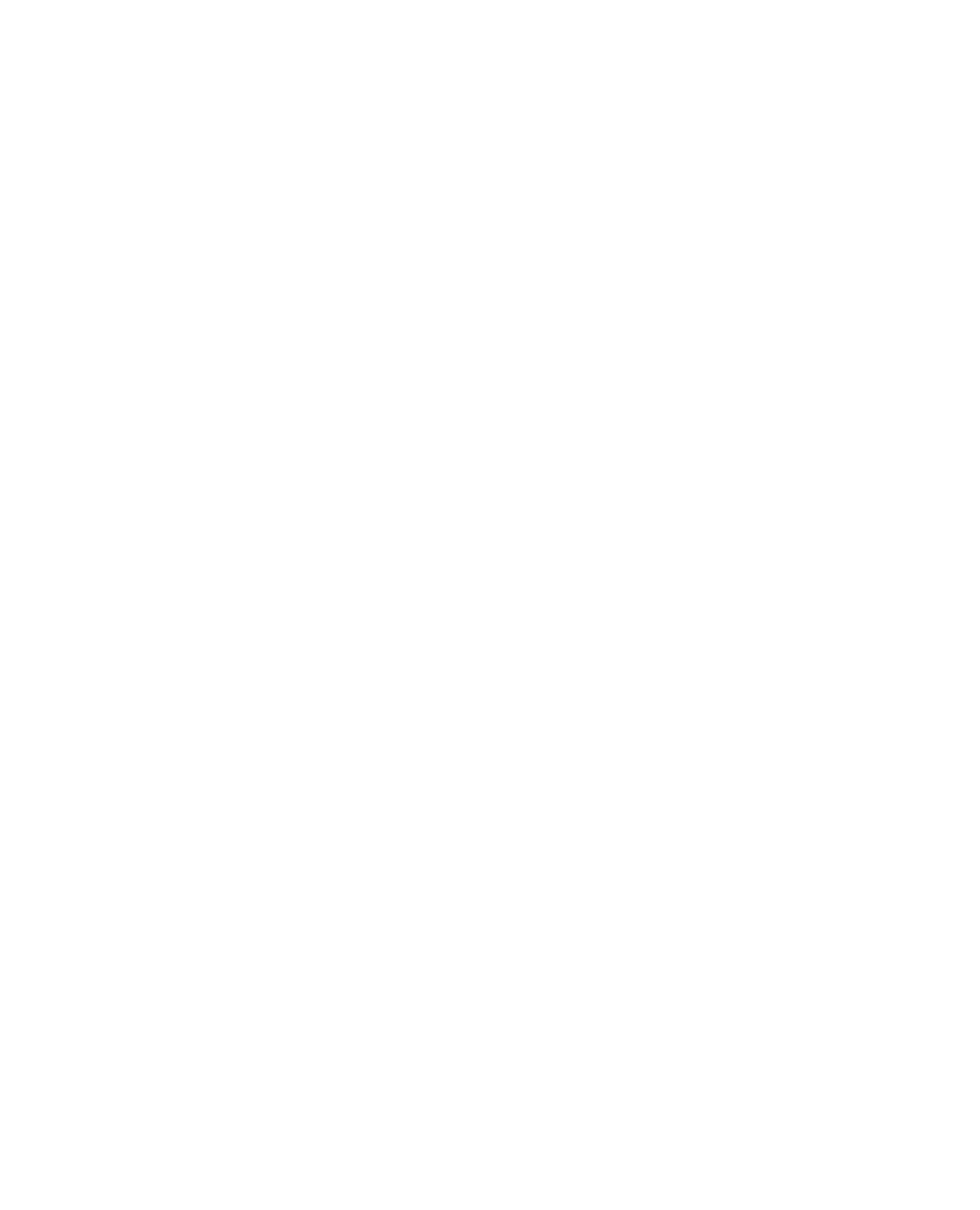

FIGURE 21.14

Chemical structure of (a) poly(lactic acid) and (b) poly(glycolic acid).

The most frequently used biodegradable and bioresorbable synthetic polymers are poly(glycolic

acid) (PGA), PLA (Figure 21.14), and their copolymers, such as poly(lactic-

co

-glycolic acid)

(PLGA). In addition, PLA can exist as two stereoisomers poly(l-lactic acid) (PLLA) and poly(d-

lactide) (PDLA) or as a racemic mixture poly(dl-lactide) (PDLLA).

These biodegradable polymers offer the advantages such as good biocompatibility, biodegrad-

ability, bioresorbability, combined with required mechanical properties. Mechanical properties of

these polymers, such as reaction to compression, are similar to normal beef cartilage. Moreover,

they can be tailored to a wider range of properties and easily formed into the fi nal products. The

most important feature is that FDA has approved the use of these polymers in human body for medi-

cal and pharmaceutical purposes. The PLA, PGA, and their copolymers are biodegraded into lactic

and glycolic acids and are then metabolized and excreted from the body as energy, carbon dioxide,

and water. PLA is more water-repellent than PGA. This material is less crystalline and more slowly

degrades. However, like cartilage, which is glassy, it is characterized by high crystallinity [54,55].

Synthetic poly-α-hydroxy ester substrates in the form of PGA- and PLLA-based scaffolds have

shown to enhance the promotion of proteoglycans, chondrocyte proliferation, differentiation, and

maturation in comparison to collagen-based scaffolds [56]. To improve the bioactivity of the syn-

thetic materials, they are used very often in combination with natural HA or collagen [57].

TPE based on hydrophilic poly(ethylene glycol)-terephthalate (PEGT) and hydrophobic PBT

block can also be used as carrier materials (scaffolds) for AC repair. The tensile modulus (

E

) and

tensile strength for 300/55/45 (PEG/PEGT/PBT) copolymer are 187.5 and 15.3 MPa, respectively,

while for 1000/70/30 they are about 34 and 5.3 MPa [46].

Synthetic scaffolds can be also produced from biodegradable elastomeric polyurethanes, which

showed evidence as materials of high cell and tissue compatibility [58]. The biodegradable porous

polyurethane scaffolds are characterized by high stimulation of seeded cells. These materials

also stimulate the growth and biosynthetic activity of joint chondrocytes and maintain the varied