Biomedical Engineering Reference

In-Depth Information

An

Escherichia coli

suspension with a concentration of 10

6

CFU/mL is employed to assess and

compare the antimicrobial properties of the Cu PIII PE and Cu/N

2

PIII PE samples at immersion

time periods of 0, 14, and 28 days (Figure 19.53b). Before they are immersed in SBF (i.e., day 0), both

Cu PIII PE and Cu/N

2

PIII PE have excellent antibacterial effects against

E. coli

, that is, 96.2% and

95.5%, respectively. This mainly stems from the surface-deposited Cu that can deliver immediate

antimicrobial effects. After immersion in SBF for 14 days, the Cu PIII PE and Cu/N

2

PIII PE still

possess good antibacterial performances against such a high cell suspension in spite of the reduced

Cu release rates. The antimicrobial effects against

E. coli

are 70.6% and 84.3%, respectively. It should

be noted that the Cu/N

2

PIII PE sample exhibits better antibacterial effects. The difference is even

more evident after immersion for 28 days. The results thus unequivocally demonstrate the excellent

antibacterial effect of Cu/N

2

PIII. The process allows for the continuous release of buried Cu to retain

the surface antibacterial ability for a longer period of time. In separate experiments, the prepared

samples were stored under room temperature in air for 6 weeks and their antimicrobial effects were

compared with those of freshly prepared samples. The antimicrobial effects against

E. coli

were

found to hardly change, thus indicating excellent long-lasting effects during normal storage.

It is well known that the antimicrobial properties are primarily related to the release of the

antibacterial reagent, Cu. In the absence of gettering effects, Cu out-diffusion from the substrate is

believed to follow Fick's fi rst law of diffusion [207,208]:

d

N

DS

d

C

d

x

,

___

___

d

t

=

-

(19.4)

where

N

is the amount of copper, d

C

/d

x

is the Cu concentration gradient with distance,

t

is the time,

S

is the surface area of the samples, and

D

is the diffusion coeffi cient. Here,

S

is the same

and d

C

/d

x

is more or less the same because the same Cu PIII conditions are used for both the samples. Conse-

quently, the Cu diffusion rate, d

N

/d

x

, depends mainly on the diffusion coeffi cient,

D

. A diffusion

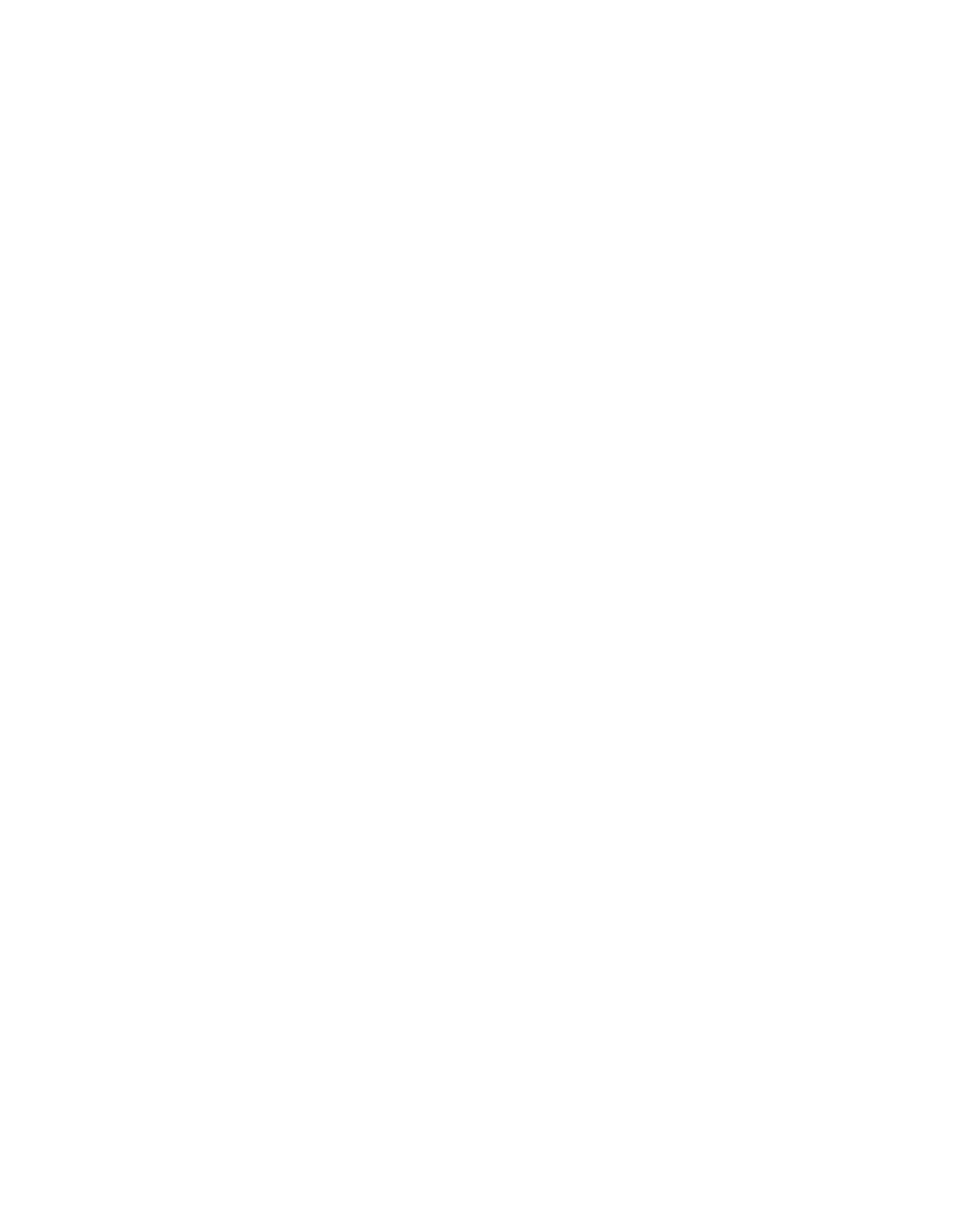

process from the substrate consisting of two zones is being proposed, as schematically described in

Figure 19.54. Diffusion in zone B is described by the above equation whereas that in zone A also

depends on the chemistry and gettering effects between Cu, N, and the PE matrix.

Plasma immersion ion implantation is an effective method to introduce a large quantity of metal

inorganic antimicrobials like Cu into organic medical polymers such as PE up to a depth of several hun-

dred nanometers without causing appreciable damage to the polymer matrix. The use of N

2

PIII in con-

cert with Cu PIII produces new polar unsaturated functional groups such as C

N in the

near-surface of the polymer. They play an important role in regulating the out-diffusion rate of Cu and

prolonging the antibacterial effects signifi cantly. It demonstrates that an inorganic antimicrobial agent

can be effectively incorporated into an organic biomedical polymer and by using a nitrogen plasma

=

N and

-

C

≡

Cu

Polyethylene

Cu

SBF

Cu

Cu

B

A

FIGURE 19.54

Schematic diagram illustrating two zones in the Cu-implanted polyethylene. (From Zhang,

W., Zhang, Y.H., Ji, J.H., Yan, Q., Huang, A.P., and Chu, P.K.,

J. Biomed. Mater. Res.: Part

A

, in press

DOI.10.2002. With permission.)