Biomedical Engineering Reference

In-Depth Information

better blood compatibility is necessary. In this section, elemental-doped and undoped DLC fi lms

prepared by PIIID under different conditions are described.

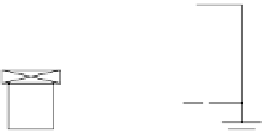

The undoped and doped DLC fi lms were fabricated by PIIID. Acetylene (C

2

H

2

) gas was used

to produce carbon plasma for fi lm deposition. The dopants were introduced into the vacuum cham-

ber simultaneously via thermal- or electron-induced evaporation. Phosphorus- and calcium-doped

DLC fi lms were fabricated by using this method. C

2

H

2

and Ar gases were bled into the chamber

through two individual fl ow controls and inlets on top of the chamber. Figure 19.29 illustrates the

schematic diagram of the basic experimental setup of PIIID for DLC fi lms synthesis. By using the

PIIID system with C

2

H

2

, amorphous hydrogenated carbon fi lms can be produced. For elemental-

doped DLC fi lm fabrication, however, a dopant source is added to the system to provide additional

ions for fi lm deposition. In general, elemental powders are placed in a container and evaporated by

means of heated fi lament and electron bombardment. The dopant vapor is created, mixed with the

C

2

H

2

gas, and eventually ignited into plasma by RF sources for fi lm deposition as demonstrated in

Figure 19.30.

19.5.1.1 Infl uence of Flow Ratio on Structure and Hemocompatibility

Using PIIID, DLC fi lms are fabricated on silicon substrates at room temperature. By changing the

C

2

H

2

to Ar (

F

C

2

H

2

/

F

Ar

) fl ow ratio during deposition, the effects of the reactive gas pressure and fl ow

ratio on the characteristics of the DLC fi lms are systematically examined to correlate to the blood

compatibility. The Raman D-band to G-band intensity ratio is consistent with the adherent platelet

quantity, both the ratio and platelets fi rst increasing and then decreasing with higher

F

C

2

H

2

/

F

Ar

fl ow

ratios. This implies that the blood compatibility of the DLC fi lms is infl uenced by the ratio of sp

3

to

sp

2

, not by the absolute sp

3

or sp

2

content.

Using stylus profi lometry, the fi lm thicknesses are determined to be about 100, 130, 200, 240,

and 300 nm at

F

C

2

H

2

/

F

Ar

fl ow ratios of 0.4, 0.6, 0.8, 1.0, and 1.2, respectively. As expected, the

deposition rate is higher with increasing C

2

H

2

fl ow rates. Figure 19.31 exhibits the 3D atomic force

microscopy (AFM) morphology of the DLC fi lms at

F

C

2

H

2

/

F

Ar

fl ow ratios of 0.6 and 1.2. The surfaces

Gas inlets (C

2

H

2

and Ar gases)

RF antenna

system

Plasma

cluster

Vacuum

chamber

Substrate

Sample

stage

Negative (DC or

pulsed) bias voltage

To vacuum

pump

FIGURE 19.29

Schematic diagram of PIIID system for DLC synthesis.