Biomedical Engineering Reference

In-Depth Information

(ICPMS). The Ni and Ti concentrations released from the control sample are 30.2324 and

0.1575 ppm, respectively. The Ni concentrations from the nitrogen-, acetylene-, and oxygen-

implanted samples are only 0.0117, 0.0082, and 0.0123 ppm, respectively. The Ti concentrations

from the nitrogen- and acetylene-implanted samples are 0.0527 and 0.0057 ppm, respectively. The

Ti concentration from the oxygen-implanted sample is undetectable. The results reveal that the

amounts of Ni leached from all the treated samples are signifi cantly reduced. The leached amount

is only about 0.03-0.04% of that of the control sample.

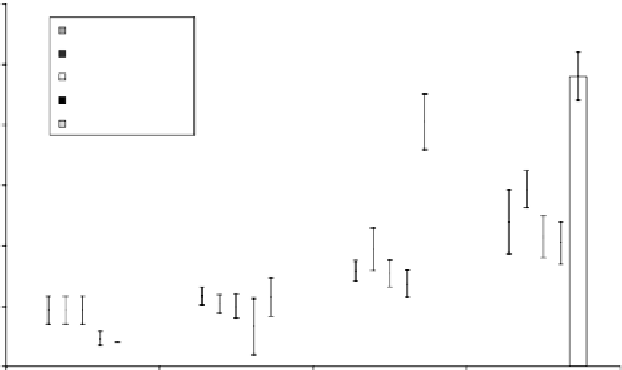

All the plasma-implanted samples are well tolerated by the EGFP-expressing osteoblasts as

shown in Figure 19.28. After culturing for 2 days, the cells start to attach to and proliferate on

all the samples. After 4 days, cell proliferation on the untreated NiTi alloy samples was slightly

higher than that of the nitrogen, oxygen, and acetylene PIII samples. However, the nitrogen PIII

samples exhibit the highest degree of cell proliferation among the samples after 6 and 8 days of

culturing. Cell proliferation on the acetylene- and oxygen-implanted samples was slightly lower

than that on the NiTi control sample after 6 and 8 days, but the difference not signifi cant.

Oxygen, nitrogen, or acetylene PIII can effectively suppress the leaching of nickel from the

NiTi alloys. The enhancement phenomenon can be attributed to the high affi nities of Ti toward

N, C, and O as compared to Ni under high-temperature annealing. It provides a driving force to

enrich the surface with the element forming a stronger chemical bond. The heat of formation of

the lowest titanium oxide is

913 kJ/mole

while that of NiO is

244 kJ/mole

[137]. The heat of

-

-

305.6 kJ/mole

while nickel nitrides such as TiN

3

TiN are unstable with respect

to TiN [138]. The heat of formation of TiC is

formation of TiN is

-

773 kJ/mole

[139] while that of NiC is not well

-

established since the Ni

C phase diagram does not show stable carbides. The term nickel carbide

may only stand for interstitial solid solutions of C in Ni, which possess the NaCl structure [140].

Therefore, the formation of titanium oxide, nitride, and carbide is energetically favored over the

nickel counterparts and this is believed to account for the suppression of Ni in the implanted and

annealed region. It should be noted that the degree of suppression does depend on the implanta-

tion parameters as reported by Tian et al. [137] in their study of the suppression of nickel in the

stainless steel surface after nitrogen PIII.

-

30

NiTi

NiTi-N

NiTi-O

NiTi-C implanted

Empty well

25

20

15

10

5

0

2

4

6

8

Days

FIGURE 19.28

Cell proliferation on various NiTi alloys versus number of days. (From Yeung, K.W.K. et al.,

J. Biomed. Mater. Res.

,

72A, 238, 2005. With permission.)