Biomedical Engineering Reference

In-Depth Information

300

250

200

150

100

50

0

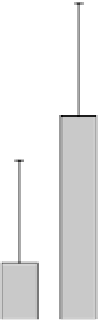

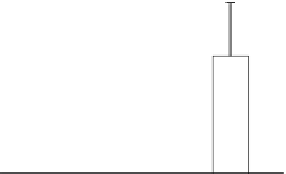

FIGURE 19.24

Bioactivity of the four samples as determined by the precipitation of calcium phosphate

from a simulated body fl uid after 24 h. The calcium phosphate precipitates are dissolved in HCl, and the

calcium concentration in the solution is determined. The values are scaled to those of the NaOH-treated sam-

ple as 100%. Labels indicate Ti (untreated control), Ti PIII (Na plasma-implanted sample), Ti-II (beam-line

implanted sample), and Ti-NaOH (NaOH-treated sample). (From Maitz, M.F. et al.,

Biomaterials

, 26, 5465,

2005. With permission.)

the higher activity of the ion species in the plasma than in the solution, leading to a higher rate of

titanate formation. However, more work is needed to verify this postulate.

19.4 SURFACE MODIFICATION OF NiTi ALLOY

Nickel titanium (NiTi) shape memory alloys are promising materials for surgical implants in orthope-

dics because of their unique shape memory effects (SME) and super elasticity (SE) that other common

orthopedic materials such as stainless steels and titanium alloys do not possess. Their mechanical

properties are also closer to those of cortical bones than stainless steels and titanium alloys. In terms

of wear resistance, the materials are better than CoCrMo alloys used in bone trauma fi xation [85]. Sev-

eral other favorable properties of the materials have also been investigated [86-98] and good biocom-

patibility has been reported [85,89,99-109]. However, some negative effects have also been pointed

out. For example, Berger-Gorbet et al. have found that the osteogenesis process and osteonectin syn-

thesis activity in NiTi alloys are unfavorable compared to stainless steels and titanium alloys [110]. Jia

et al. in their study revealed that the cell death rate was severe on NiTi alloys [111]. These problems

are believed to stem from the poor corrosion resistance of the materials, thereby leading to an increase

of the cytotoxicity. It is most likely that some toxic components released from the substrate cause cell

death rather than apoptosis [112]. Shih et al. [113] reported that the supernatant and corrosive products

from NiTi might result in the death of smooth muscle cells, especially when the amount of released

nickel is higher than 9 ppm. A few other studies have reported that nickel ions [102,103] leached from

the alloys cause allergic reactions in nickel hypersensitive patients [114-117]. While the homogeneity

of the material microstructures and the surface morphology may alter the anticorrosion ability of NiTi

alloys, there is no doubt that the corrosion resistance and antiwear properties of the materials must be

enhanced before the materials can be widely used clinically, especially as orthopedic implants with

couplings where fretting is expected.