Biomedical Engineering Reference

In-Depth Information

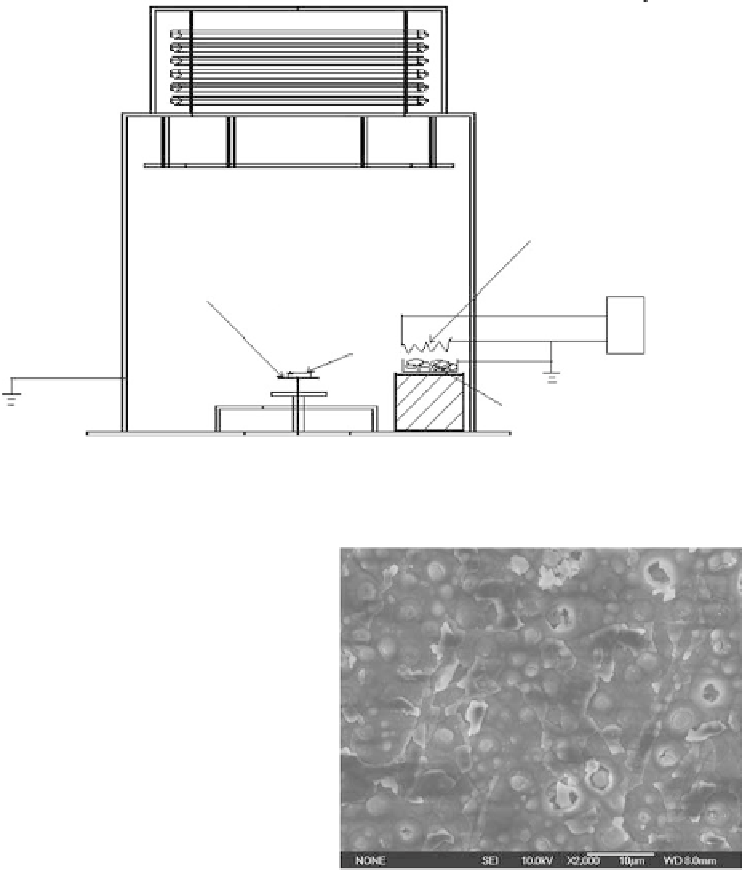

There are practical diffi culties in the conduction of PIIID of sodium and calcium by the con-

ventional cathodic arc technique because of their low melting point and high reactivity in air and

with moisture. The low melting point makes stable and long implantation very diffi cult and the high

reactivity imposes diffi culty in handling as well as in the construction of a suitable cathode. The

experiments used an evaporating ion source invented by the research staff in the City University of

Hong Kong [79-81], as shown in Figure 19.17. In this source, instead of using electrical triggering

to form the plasma, evaporation is used and on account of the high ionizing effi ciency of Na and Ca,

an intense Na and Ca plasma plume can be readily formed to conduct PIIID.

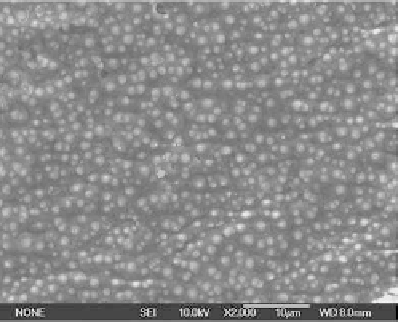

The implanted titanium samples possess a rough surface. Ball-like protuberances can be

observed on the surface of the titanium sample implanted at 10 kV, as shown in Figure 19.18a. The

titanium sample implanted at 20 kV is different from that implanted at 10 kV, and exhibits more sali-

ent features (Figure 19.18b). It can be observed that a new layer has formed on the surface of these

RF

Tungsten

filament

Negative bias voltage

+

−

Samples

Ca source

FIGURE 19.17

Schematic diagram of the Ca/Na PIIID system.

(a)

(b)

FIGURE 19.18

SEM micrographs of the Ca ion-implanted titanium: (a) 10 kV of bias voltage and (b) 20 kV

of bias voltage. (From Liu, X.Y. et al.,

Surf. Coating Tech.

, 191, 43, 2005. With permission.)