Biomedical Engineering Reference

In-Depth Information

(a)

(b)

Outermost layer

Higher magnification

100 nm

200 nm

200 nm

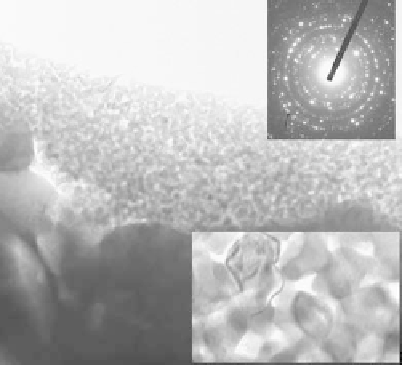

FIGURE 19.15

Cross-sectional TEM views of the as-sprayed nano-TiO

2

coating: (a) coating surface and

(b) coating interior. (From Liu, X.Y. et al.,

Biomaterials

, 26, 6143, 2005. With permission.)

(a)

(b)

Apatite layer

TiO

2

coating

Resin

Electron image 1

30

µ

m

FIGURE 19.16

Surface (a) and cross-sectional (b) views of the hydrogen PIII nano-TiO

2

coating after soak-

ing in SBF for 2 weeks. (From Liu, X.Y. et al.,

Biomaterials

, 26, 6143, 2005. With permission.)

nanostructured surface possesses apatite formability. It can thus be inferred that the bioactivity

of the plasma-sprayed TiO

2

coating depends on two factors: nanostructured surface composed of

enough small particles and hydrogen incorporation.

It has been suggested that OH groups on ceramic surfaces are effective in inducing the forma-

tion of an apatite layer. For instance, gel-derived TiO

2

has been shown to induce surface apatite

formation, but single crystal anatase and titania synthesized by hydrothermal methods cannot do so

[65]. The difference is believed to be because of the Ti

Ti-OH functional groups forming a negatively

charged surface on the titania gel. It is also believed to be one of the reasons for the surface bioactiv-

ity of the hydrogen PIII nano-TiO

2

and the lack of OH groups on the as-sprayed TiO

2

coatings.

The as-sprayed TiO

2

coating is highly oxygen-defi cient. While the outermost surface of the

as-sprayed TiO

2

coating can be immediately reoxidized via oxygen adsorption after it is exposed

to air [66], the subsurface region in the coating is still oxygen-defi cient. During hydrogen PIII,

hydrogen ions react with the outermost bridge oxygen to form Ti

-

Ti-OH bonds because the reaction

is energetically favorable, and two Ti(IV) are reduced to Ti(III) [67]. Eventually, a hydrogenated

-