Biomedical Engineering Reference

In-Depth Information

clinical success of orthopedic/dental implants. Osteoblast proliferation was observed to be signifi -

cantly higher on nanophase alumina, titania, and HA in comparison with their conventional coun-

terparts. Furthermore, compared with conventional ceramics, synthesis of alkaline phosphatase and

deposition of calcium-containing minerals were signifi cantly enhanced on osteoblasts cultured on

nanophase ceramics. A nanostructured bioactive TiO

2

surface can be produced using a combination

of nanoparticle plasma spraying and hydrogen PIII.

Commercially available nanosized TiO

2

powders were deposited onto titanium alloys using a

atmospheric plasma spraying (APS) system under the modifi ed spray parameters. Argon (40 slpm:

standard liter per minute) and hydrogen (12 slpm) were used as the primary and auxiliary arc gases,

respectively. The feeding rate of powders was about 10 g/min using argon (3.5 slpm) as the carrier

gas. The arc current and voltage were 600 A and 70 V, respectively. The spraying distance was

100 mm. The thickness of the coatings was about 100 µm.

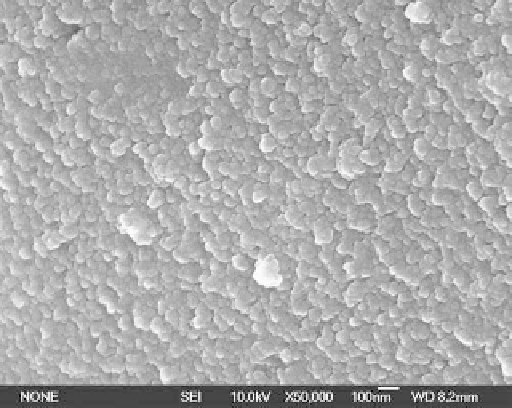

The high-magnifi cation SEM view of the coating surface indicates that the surface of the

nano-TiO

2

coating comprises particles less than 50 nm in size (Figure 19.14). The cross-sectional

TEM views of the as-sprayed nano-TiO

2

coating also reveal that the outermost surface is com-

posed of grains less than 50 nm (Figure 19.15a) and are consistent with the SEM results depicted

in Figure 19.14. The thickness of this outer layer is about 500 nm. In the interior of the coating,

most of the grains exhibit a columnar morphology with a diameter of about 100-200 nm, as

shown in Figure 19.15b. The difference in the crystal growth between the surface and the interior

of the coating depends mostly on the thermal history. During plasma spraying, the bulk of the

coating tends to possess larger columnar grains due to the continuous heat provided by the plasma

and subsequent melt, whereas the surface grains are subjected to less heating.

Hydrogen was implanted into the as-sprayed nano-TiO

2

coating using a multifunctional plasma

immersion ion implanter

[36,62,63]. The plasma chamber was evacuated to a background pressure of

0.6 Torr, and then high-purity hydrogen gas was bled into the vacuum chamber to establish a work-

ing pressure of 0.5 mTorr. The instrumental parameters were as follows: pulse voltage 30 kV, pulse

frequency 200 Hz, pulse duration 30 µs, RF discharge power 1000 W, and implantation time 2 h.

After immersion in SBF for 2 weeks, the surface of the hydrogen PIII nano-TiO

2

coating

was completely covered by an apatite layer, as shown in the surface views (Figure 19.16). The

results obtained from our research indicate that only the hydrogen PIII nano-TiO

2

coating with

FIGURE 19.14

Higher magnifi cation surface SEM views of the sprayed TiO

2

and nano-TiO

2

coating. (From Liu,

X.Y. et al.,

Biomaterials

, 26, 6143, 2005. With permission.)