Biomedical Engineering Reference

In-Depth Information

17.6.2 P

OLYMERIC

C

OATINGS

For a number of implants, like for instance heart valves, the mechanical characteristics of the device

direct the choice of material. It is not always possible to choose a material that combines both neces-

sary mechanical characteristics and blood compatibility of the surface. Then often a polymeric coat-

ing is applied to the device. These coatings have several advantages since they can guide the surface

characteristics of the device as well as act as a drug depot from which controlled, local release can

take place.

65

In case of blood-contacting devices, a number of coatings have been designed. There

are several groups of different coatings that aim to inhibit biomaterial-induced thrombus formation

in a specifi c manner.

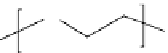

i. Coatings that present polymeric poly(ethylene oxide) (PEO) or poly(ethylene glycol) (PEG)

on their surface have been extensively studied in the last years.

66

-

70

Actually, PEO and PEG

are the same molecule as seen in Figure 17.11 and for the remainder of this chapter will be

called PEG. These coatings aim to reduce the adhesion of proteins and cells. The chains of

the hydrophilic PEG immobilize water molecules close to the surface, and this high water

content is an unfavorable condition for the adhesion of plasma proteins, platelets, and cells

like leukocytes. Therefore these PEG coatings are often referred to as protein-repellent

surfaces.

These coatings have been applied on a wide variety of materials, but there are some drawbacks of

PEG coatings. First of all, they are relatively diffi cult and thus expensive to produce on a large scale.

It is not very diffi cult to attach PEG molecules to a surface on laboratory scale (square centimeters)

but it is however quite a challenge to produce these coatings on a square meter scale, especially

with a constant and high quality. Moreover these coatings are only useful when they can be handled

without chance of damaging the coating. Even the smallest imperfection of the surface may open a

possibility for proteins to adsorb and coagulation or infl ammation to start. Although it is feasible to

prepare perfect surfaces in the laboratory, industrial scale production of such surfaces is not trivial.

Additionally, some recent

in vivo

studies have produced disappointing results of these coatings, with

the gain in blood compatibility being modest at best.

71,72

ii. Hydrogels and hydrophilic polymers are also being used to coat blood-contacting devices.

The advantage of these coatings is that their relatively high hydrophilicity, and subsequently

high water content, has been shown to decrease platelet adhesion and protein adsorption.

These coatings can be used in combination with a large variety of materials but the solid

attachment is not always straightforward. Since these hydrophilic coatings adsorb water,

they have the tendency to expand and when not attached properly to the surface, they will

detach from the device. The application of a base coating, which will anchor the main coat-

ing is often necessary. The fact is that the application of a hydrophilic coating on a medical

device is not trivial and requires input from both chemists and engineers.

73

The hydrophilic coatings can also be used as a drug depot since it is mostly straightforward in incorpo-

rating therapeutic drugs.

65,74,75

Upon contact with blood, the drug is slowly released, or in some cases

exposed, at the surface. In this way drug release occurs at the site where it is most needed, namely at

the surface of the device. Systemic application of drugs in the circulation has a disadvantage as limited

O

OH

n

H

FIGURE 17.11

Chemical structure of poly(etheylene oxide), which is also known as poly(ethylene glycol).