Biomedical Engineering Reference

In-Depth Information

500

µ

m

a

b

c

d

100

µ

m

g

e

VFP = 0.35

f

h

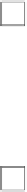

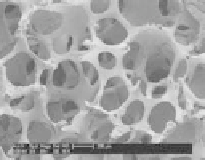

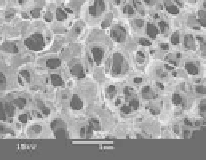

FIGURE 1.8

Typical structures of porous ceramics produced by different techniques: (a) porous hydroxya-

patite produced by the powder method combined with PVA as a porogen additive [205], (b) porous alumina by

freeze-drying method [170], (c) porous hydroxyapatite by gelcasting method [181], (d) bioactive glass foams by

sol-gel technique [188], (e) porous β-TCP by solid free-form technique [211], (f) β-TCP

+

hydroxyapatite foam

produced by the replication technique [207], (g) porous bioglass-based glass-ceramic foam by the replication

technique [80], and (h) porous structure of cancellous bone [215].

TABLE 1.12

Advantages of the Replication Technique over Other Methods

1. Cancellous bone-like macroporous structure

The porous structure produced by the replication technique is very similar to cancellous bone: highly porous network

with open and highly interconnected porosity, compared with the rest of the techniques (see Figures 1.8 (f, g, h)).

2. High commercialization potential

This technique is the simplest and most cost-effective method, and thus most suitable for commercialization, for

example, compared with SFF. SFF-RP, which are expensive processes, it may be a method for producing specifi c and

complex scaffold architectures.

3. Safety

It does not involve any toxic chemicals, compared with sol-gel and gelcasting techniques, which use HF to accelerate

polymerization.

4. Irregular or complex shape production ability

It can produce scaffolds of irregular or complex shapes, compared with standard dry powder processing or sol-gel-based

methods.

1.4.2 F

ABRICATION

OF

C

OMPOSITE

S

CAFFOLDS

The fabrication of polymer-ceramic composite scaffolds is based on conventional processes used

for neat polymeric scaffolds. Numerous techniques have been developed to process porous poly-

mer scaffolds for use in tissue engineering. Table 1.13 lists currently applied 3-D polymer scaf-

fold fabrication technologies, based on Ref. 1. Excellent reviews can be found in the literature

[1,216 -219].

While intensive efforts have been made to develop the processing technologies of polymer scaf-

folds, relatively less attention has been paid to the fabrication of porous composite scaffolds. Among

the technologies in Table 1.13, solvent casting with or without particle leaching [146,150,153,154]

and TIPS combined with freeze-drying [109-112,144,145] seem to be the most applied method to

the fabrication of polymer-ceramic composite scaffolds. In addition to these methods, there are