Biomedical Engineering Reference

In-Depth Information

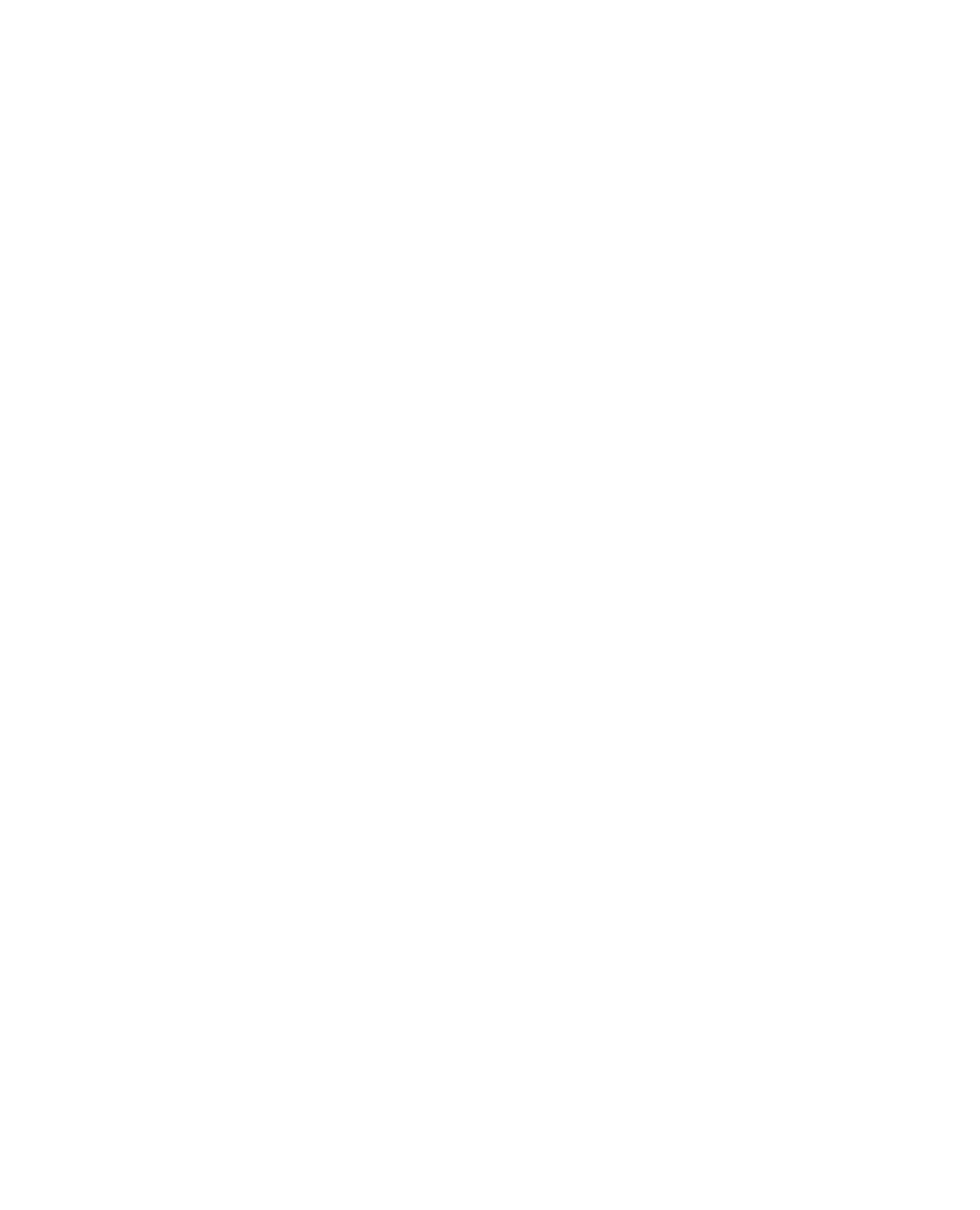

Ceramic powder

Add

Dispersant, surfactant,

monomer, cross-linker

Prepare suspension from the powder

Foam the suspension using one of the

foaming techniques in Table 2.16

Add

Initiator, catalyst

While the foamed suspension is poly

merized to form a gel, cast the gel

Dry and sinter the green body

Ceramic foam

FIGURE 1.5

Flowchart of the gelcasting method to produce a ceramic foam.

respectively, in the case of porous hydroxyapatite [173,181,183,185]. It is worthwhile noticing that

there is a narrow time-temperature window for densifi cation of foams made from bioactive glasses,

which are prone to crystallize while sintering by viscous fl ow. Hence the production of bioactive

glass foams by powder-based methods presents diffi culties [80].

1.4.1.2 Sol-Gel Techniques

1.4.1.2.1

Sol-Gel Process and Synthesis of Aerogel Ceramics

The sol-gel process is a well-developed, robust, and versatile “wet” technique for the synthesis of

ceramics and glasses. By applying the sol-gel process, it is possible to fabricate inorganic mate-

rials in various forms: ultrafi ne or spherical shaped powders, thin fi lm coatings, ceramic fi bers,

microporous inorganic membranes, monolithic ceramics and glasses, and extremely porous aerogel

materials [186].

The processing path of aerogel ceramics starts with an alkoxide precursor. Alkoxide precursors,

such as tetraethyl orthosilicate (TEOS) and triethoxyl orthophosphate (TEP), undergo hydrolysis

and condensation reactions to form a sol. In case of silicate precursors, polymerization of -Si-OH

groups continues after hydrolysis is complete, beginning the formation of the silicate (-Si-O-Si-)

network. The network connectivity increases until it spans throughout the solvent medium. Eventually

a wet gel forms. The wet gel is then subjected to controlled thermal processes of aging to strengthen

the gel, drying to remove the liquid by-product of the polycondensation reaction, and thermal sta-

bilization (or sintering) to remove organic species from the surface of the material; and as a result,

a porous aerogel forms [2,187].

1.4.1.2.2

Production of Highly Porous Glasses

Highly porous glasses (or glass foams) have been developed by a slightly modifi ed sol-gel pro-

cess [188]. The sol-gel process is based on the polymerization reactions of metal alkoxide precur-

sors (usually TEOS and TEP). These precursors are dissolved in a solvent, and a gel is formed by

hydrolysis and condensation reactions. The gel is then subjected to controlled thermal processes of

aging to strengthen the gel, drying to remove the liquid by-product of the polycondensation reac-

tion, and thermal stabilization/sintering to remove organic species from the surface of the material

(500-800°C). Sol-gel derived glass scaffolds are obtained by directly foaming the sol with the use