Biomedical Engineering Reference

In-Depth Information

13.2.4.1

Fabrication of an Optically Controlled Polypyrrole Microstructure

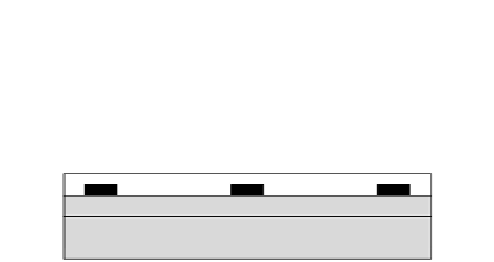

An n-type Si wafer with an implanted p-type top layer was used as a substrate. A thin metal fi lm was

deposited and patterned on the back and front sides of the substrate. A thin layer of SiO

2

was then

sputtered and patterned on the front side of the wafer to protect exposed Si surface from contact with

the electrolyte solution (Figure 13.11). A second layer of metal was deposited and patterned into 50 µm

wide strips on top of the oxide layer to provide a seed layer for PPy deposition. The two metal layers

and oxide layer were patterned such that both metal fi lms were electrically connected, thus provid-

ing PPy with an electrical contact to the p-doped side of the photodiode. PPy was electrochemically

deposited on the seed layer from an aqueous solution of pyrrole monomer to a thickness of 4 µm.

13.2.4.2

Operation of the Device

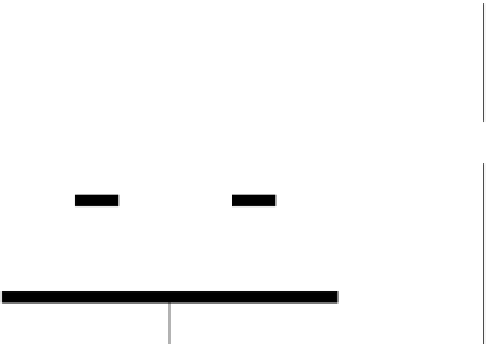

The fi nished device was placed in an aqueous solution of NaDBS and biased at

V

bias

2.25 V.

The displacement of the PPy in the direction normal to substrate surface was then measured by a

profi lometer as incident light was fi rst switched on and then switched off (Figure 13.12).

The maximum contraction or expansion of the actuator due to light modulation (

T

max

)

was measured to be

=

∼

90 nm, which is

∼

2% of the PPy thickness as deposited. As seen from

+

V

bias

−

Gold film

Polypyrrole

SiO

2

film

Si pn junction

Incident light

Electrolyte

solution

FIGURE 13.11

Operation of PPy microactuator integrated with Si photodiode.