Biomedical Engineering Reference

In-Depth Information

distance between the objective and the measured PPy line, limiting the imaging to lower power

or long-working distance objectives. Nevertheless, optical imaging has the added advantage of

allowing video microscopy with easy visualization of the time course of PPy thickness change.

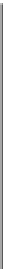

The change of PPy line thickness with voltage applied between PPy WE and gold CE, measured

with profi lometry and confi rmed with optical microscopy, is shown in Figure 13.10.

The measurement shown in Figure 13.10 is taken after the PPy has been electrochemically

cycled at least three times. This procedure is used because the fi rst expansion of a PPy is gener-

ally much larger than that on later cycles. The original thickness of the PPy fi lm in Figure 13.10

was 6.5 µm just after synthesis, and as seen in the fi gure, the thickness of the fi lm does not

return to this value once it has been subjected to a redox cycle.

An important issue that becomes apparent after PPy test lines have been reduced and oxi-

dized a few times involves adhesion failure between PPy and gold seed layer. There is no cova-

lent attachment between the gold fi lm and the electropolymerized PPy, and the polymer tends

to detach from gold after a few redox cycles due to its linear expansion of a few percent, which

is relative to the supporting electrode. This is the same problem that also plagues the designers

of bilayer actuators, and several solutions involving increased roughness of the gold (through

varying parameters of gold electrochemical deposition) or other electrode materials have been

proposed in the literature.

10,11

We have used a novel electrode geometry that was used to prevent

adhesion failure between PPy and gold in the microvalve design (Section 13.3).

13.2.4 I

NTEGRATION

OF

P

OLYPYRROLE

M

ICROSTRUCTURES

WITH

S

ILICON

D

EVICES

PPy test lines described in Section 13.2.3.2 have been fabricated using photolithography on a planar

substrate. This fabrication methodology is fully compatible with semiconductor microfabrication

with the implication that PPy microstructures can be potentially integrated on the same substrate

with such semiconductor devices, transistors, and optical diodes. Such integration opens up a realm

of interesting possibilities of using PPy actuators as mechanically active elements integrated on a

single chip with electronic control circuitry and optical remote communications and power delivery

with potential applications in microrobotics. A proof-of-concept integration of PPy test lines with

electrochemically controlled thickness and a silicon pn junction that can function as a photodiode

is described in Sections 13.2.4.1 and 13.2.4.2. Connection to the pn junction allowed optical control

of actuation, potentially enabling microfl uidic and lab-on-chip devices, which could be remotely

controlled by a laser or a photodiode across a layer of biological fl uid.

8

Polypyrrole thickness

7.8

7.6

Applied voltage =

V

WE-CE

V

WE-CE

(

−

2.5 V) =

V

WE-REF

(

−

1V)

7.4

7.2

7

6.8

0

−

2.5

−

2

−

1.5

−

1

−

0.5

Applied voltage (V)

FIGURE 13.10

Change in thickness of polypyrrole with applied voltage measured by profi lometry.