Biomedical Engineering Reference

In-Depth Information

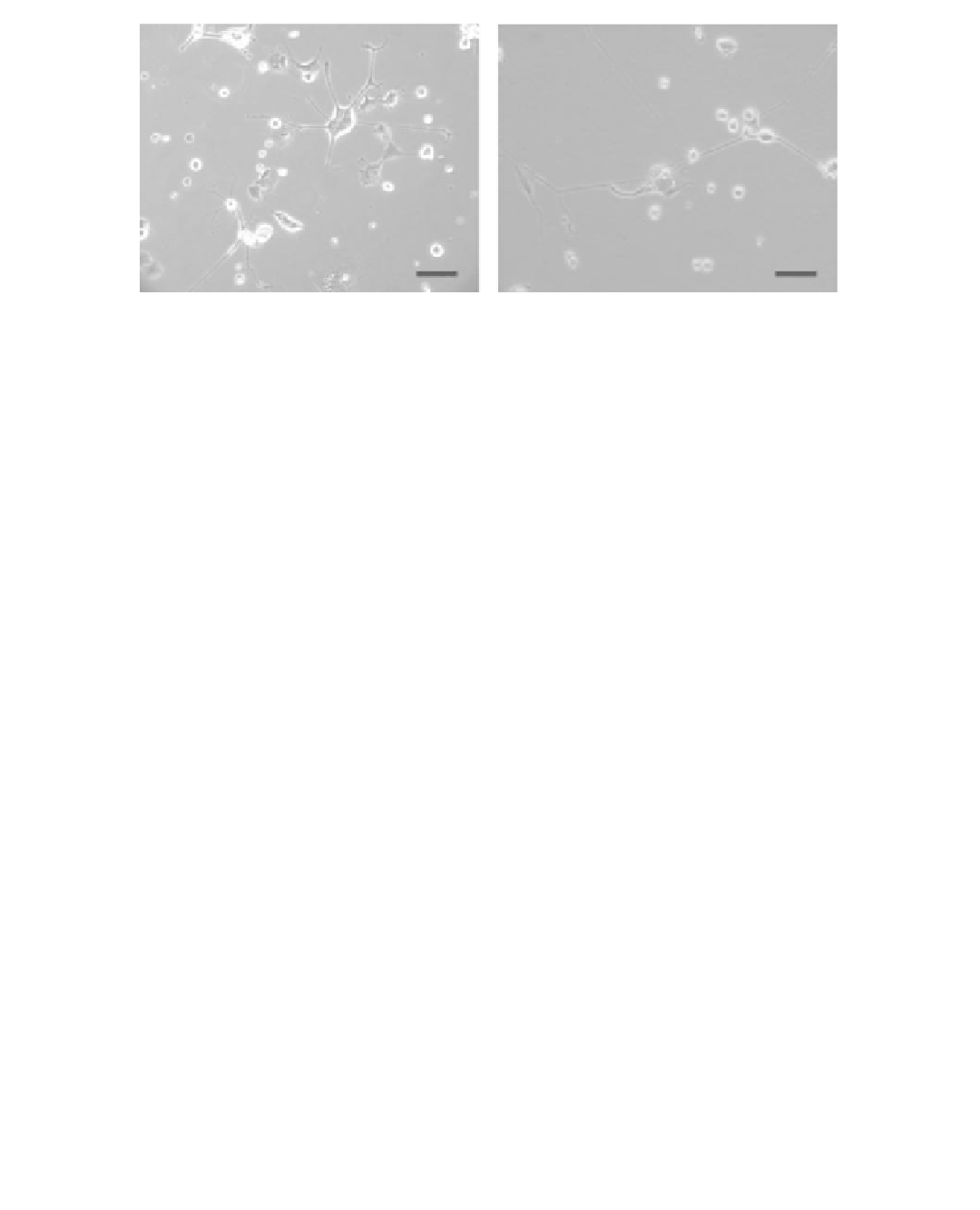

(a)

(b)

FIGURE 11.58

Optical micrographs taken 1 month after the cells were jetted (a) control CAD cells and

(b) CAD cells that were jetted at 7 kV. Scale bar—100 μm. (Reprinted from Eagles, P.A.M., Qureshi,

A.N., and Jayasinghe, S.N.,

Biochem. J.

, 394, 375, 2006. © Elsevier Science. With permission.)

were then counted using a haemocytometer under a phase-contrast microscope. A 2-5 mL por-

tion of cell suspension containing (1-2)

10

6

cells/mL was used for electrospraying. The CAD

cell suspension was electrosprayed at an electric fi eld strength of 0.47-0.67 kV/mm. The results

showed that CAD cells can be aerosolized and still remain viable at applied voltages in a range

of 7-10 kV. The cells appeared normal and continued to divide at rates similar to those shown

by control samples. When placed in a serum-free medium, the cells can undergo differentiation

for at least 1 month. Figure 11.58a illustrates the control CAD cells and Figure 11.58b shows the

electrosprayed CAD cells at 7 kV after 1-month incubation, demonstrating that the electrosprayed

cell retained the ability after electrospraying. The results showed that at the applied voltages of

7 and 10 kV, the average diameter of the spots ranged from approximately 300-1000 μm. There

were a greater proportion of droplets with either no cells or small numbers of cells at an applied

voltage of 7 kV. It is concluded from the research that the electrospraying technique could be used

to aerosolize and deposit neuronal cells in droplets with a controllable resolution. The investigation

opens up the possibility of using a novel approach to deposit small numbers of living nerve cells

in the fabrication of biological tissues as well as in the production of biochips and biosensors for a

range of bioengineering applications.

×

11. 3 SUMM ARY

This chapter has reviewed the electrohydrodynamic process as an effi cient and versatile technique

to prepare biomaterials in terms of their principles, processing parameters, and biomedical applica-

tions, with the emphasis on the infl uences of processing parameters on the microstructures of the

fi nal products. The biological particles, coatings, and microarrays in micrometer and nanometer

scales were successfully produced using electrohydrodynamic processing—electrospraying. The

biological materials prepared through electrospraying with the easy processability can establish a

useful starting point for utilizing these biomaterials in the drug delivery, biointerface, and biochip

applications, which would have a signifi cant impact on the production of micro- or nanostructured

biomaterials for biomedical applications. These preliminary research results have demonstrated the

capability and merits of electrohydrodynamic processing for manufacturing materials applied in

the biomedical fi elds with designed microstructure. However, in order to advance the applications

of electrospraying as an innovative technique to prepare biomaterials, the researches will require

more collaborative interdisciplinary from the different areas, such as material scientists, biological

scientists, and engineers.