Biomedical Engineering Reference

In-Depth Information

35

30

25

20

15

10

5

0

0.0

0.20

0.40

0.60

0.80

1.0

1.2

1.4

Microbead diameter (mm)

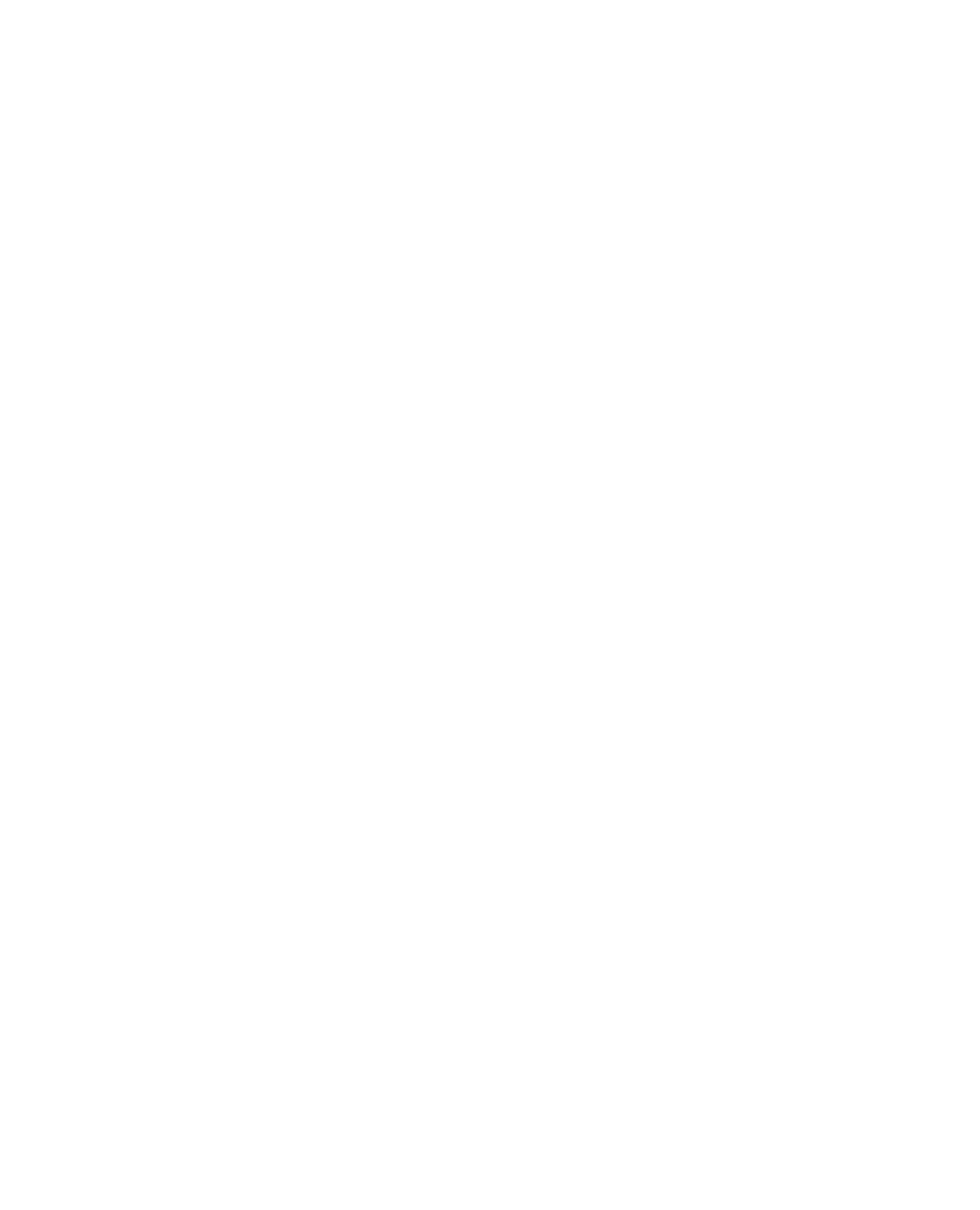

FIGURE 11.43

Electrosprayed bead diameter distributions at a 15% w/v EVA concentration and 4.0 kV

applied voltage. (Reprinted from Amsden, B.G. and Goosen, M.F.A.,

J. Contr. Release

, 43, 183, 1997. ©

Elsevier Science. With permission.)

of the incorporated particle and was approximately 0.40 and 0.45 for the encapsulated protein with

an average size of 92 and 26 µm, respectively. The experiments demonstrated that electrospraying

is capable of producing protein-loaded hydrophobic polymeric microbeads from a suspension of

protein particles in a polymer-organic solvent solution at varying protein volumetric loadings.

Watanabe et al. prepared immobilized enzyme-gel particles with high catalytic effectiveness

using an electrospraying atomization technique [100]. In the work, an aqueous sodium-alginate

solution containing enzymes was electrosprayed into a CaCl

2

solution to prepare gel beads. Sodium

alginate, calcium chloride, sucrose, and invertase were used as an immobilizing matrix, a gel-

ling agent, a substrate of enzyme reaction, and an immobilized enzyme, respectively. Figure 11.44

shows the experimental apparatus for electrospraying atomization. A sodium-alginate solution with

a concentration of 10-30 g/L containing 1.0 g/L enzyme was fl own out from a nozzle electrode.

The high DC voltages in a range of 0-5 kV were applied between the nozzle and the grounded elec-

trodes. The electrosprayed droplets of the precursor were ejected into CaCl

2

aqueous solution with a

concentration of 5-20 g/L. After the gelation in CaCl

2

solution, particles immobilizing the enzyme

were incubated at 277 K for 24 h to stabilize the gel matrices. The particles were then fi ltered using

a sheet of nitrocellulose membrane with an average pore size of 1.0 μm. The optimum immobiliza-

tion conditions were (1) an applied voltage of 5.0 kV, (2) a sodium-alginate solution concentration

of 30 g/L, and (3) a fl ow rate of 1.33

10

−2

mL/min. The relationship between the Ca-alginate

bead diameter and the applied voltage is shown in Figure 11.45. It can be seen that the decrease

in the diameter was not so sensitive to the applied voltages exceeding

V

c

. The results also showed

that the diameter of microbeads was directly proportional to the power of the volumetric fl ow rate.

The experiments demonstrated that Ca-alginate beads were prepared with a minimum diameter of

100 μm, which was one order smaller than that attained by the conventional dropping methods. In

terms of the effi ciency based on the encapsulated enzyme, the immobilized enzyme particles had

higher effectiveness factors than those prepared by the conventional methods. Electrospraying tech-

nique has been proved to be useful for enhancing the performance of immobilized enzyme particles

by producing particles with a smaller diameter.

Xu et al. used electrospraying to encapsulate BSA protein with PLA [101]. Principally, an

electrosprayed PLA droplet was generated by applying an electric fi eld to a nozzle from which

the PLA/BSA solution was pumped. The solutions were prepared by dissolving PLA in 10 mL of

×