Biomedical Engineering Reference

In-Depth Information

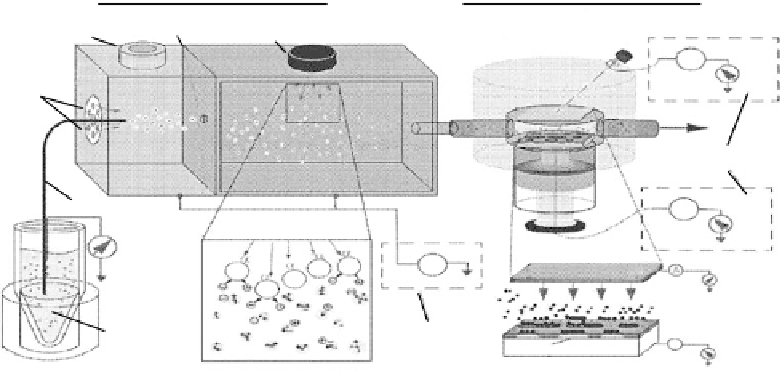

Electrospray ionization module

Nanomaterial assembly module

Orifice plate

Lens

Charge neutralizer

+V

DC

A

CO

2

/air flow

Air filter

Electrometers

V

DC

Capillary

−

A

V

DC

External

electric field

A

+V

DC

HV

N

2

N

2

N

2

A

N

2

N

2

Electrometer

V

DC

Particles in

conductive

solution

−

Charged area

A

Drop neutralization

FIGURE 11.35

A schematic diagram of electrospraying technique for controllable deposition. (Reprinted

from Welle, A.M. and Jacobs, H.O.,

Appl. Phys. Lett.

, 87, 263119, 2005. © American Institute of Physics. With

permission.)

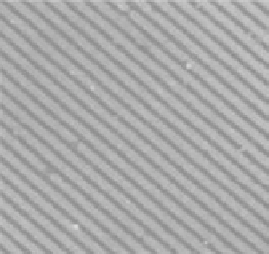

(c)

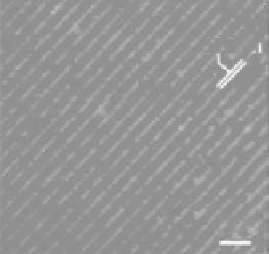

(a)

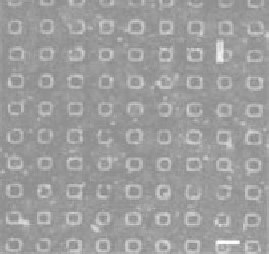

(b)

200

µ

m

200

µ

m

2

µ

m

2

µ

m

2

µ

m

FIGURE 11.36

Fluorescent microscope images

of printed proteins are as follows: (a) albumin FITC bovine,

(b) avidin sulforhodamine, and (c) albumin FITC bovine. (Reprinted from Welle, A.M. and Jacobs, H.O.,

Appl. Phys. Lett.

, 87, 263119, 2005. © American Institute of Physics. With permission.)

assembly module. The electrospraying system, which consisted of a high-voltage source, a pressure

regulator and chamber, a capillary, and a neutralization chamber, can provide a greater control

to monitor the electrospraying currents. An electrometer was used to monitor the electrospraying

current, which varied depending on

the fl ow rate, the solution properties, and the electrospraying

voltage. The highly charged primary droplets entered a neutralization chamber and formed aerosol,

which was introduced to an assembly module through an opening. An electric fi eld was applied to

bring charged biological materials into close proximity of the charged patterned substrate to attract

the oppositely charged biomaterials in an assembled way. Figure 11.36 shows fl uorescent micro-

graphs taken from different types of proteins deposited on substrates using electrospraying. All

images show patterned microstructures generated through a controlled deposition. Figure 11.36a

shows albumin fl uorescein isothiocyanate (FITC) bovine deposited onto negatively charged lines.

The albumin FITC bovine was electrosprayed in a positive ion mode to generate positively charged

protein aerosol, and then a positive potential was applied to the top electrode in the assembly mod-

ule while the

substrate was kept at ground to direct the positively charged

proteins to the substrate