Biomedical Engineering Reference

In-Depth Information

injection needles. Before electrospraying, the carbon electrode was inserted into a cylindrical brass

housing shown in Figure 11.23b. The results have shown that electrospraying can produce CA mem-

branes with a high quality and uniform thickness, which is important for a biological membrane.

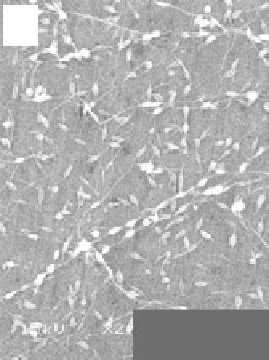

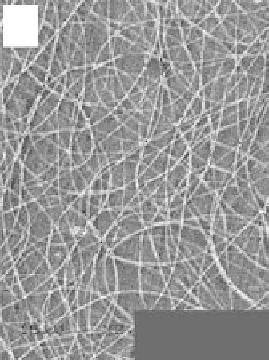

Morota et al. generated nanostructured PEO fi lms using electrospraying from an aqueous solu-

tion [75]. The fi lms fabricated through electrospraying can fi nd wide application in the fi elds of

biosensors, microfl uidic devices, antifouling, and biocompatible layers for medical devices. In this

study, the infl uences of the applied voltage and the solution properties (viscosity, surface tension,

conductivity, and molecular weight) on the microstructure of the PEO fi lms were thoroughly inves-

tigated. It was the fi rst comprehensive study on the control of nanostructured PEO polymer thin

fi lms prepared using electrospraying. By varying the applied voltage and the solution properties, the

microstructure of PEO fi lms is changed from nanospherical to nanofi brous. The study results dem-

onstrated several conclusions: (1) a higher applied voltage tended to produce fi brous microstructures;

(2) a higher polymer concentration tended to produce fi brous microstructures; (3) a higher electrical

conductivity tended to produce fi brous microstructures; (4) a higher molecular weight tended to

produce a fi brous structure, which suggested that the confi guration of the polymer chains and their

entanglement in solution contributed to the formation of the fi brous structure. The SEM images

of the electrosprayed PEO fi lms with various molecular weights are shown in Figure 11.24. These

experimental results can provide systematic information for the preparation of nanostructured PEO-

based thin fi lms using electrospraying.

Berkland et al. developed a modifi ed electrospraying technique, named fl ow-limited fi eld-

injection electrostatic spraying (FFESS) to prepare poly(d,l-lactide-

co

-glycolide) (PLG) fi lms

with various controllable micro- and nanostructures [76]. The technique provided enhanced con-

trol of surface microstructure of the PLG fi lms by injecting charge into the PLG solution using a

nanosharpened tungsten electrode. A schematic diagram of a comparison between conventional

electrospraying (CES) and FFESS is shown in Figure 11.25. The advantage is fi eld-ionization of

the polymer solution through charge injection so that an insulating solution can still be electro-

sprayed in a stable and uniform jet-spraying mode through emission from a smooth glass nozzle.

By varying the fl ow rate, the solution concentration, the applied voltage, and the electrospraying

distance, a wide variety of structures—from smooth fi lms to uniform nanoparticles—were pro-

duced using FFESS. The surface structure discretely changed from smooth to increasingly porous

to distinct particles is shown in Figure 11.26. The ability to produce biodegradable PLG polymer

(b)

(a)

(c)

10

µ

m

10

µ

m

10

µ

m

FIGURE 11.24

SEM images of electrospraying PEO fi lms from polymer with different molecular weights

are as follows: (a) 20,000, (b) 500,000, and (c) 4,000,000. (Reprinted from Morota, K. et al.,

J. Colloid Inter-

face Sci.

, 279, 484, 2004. © Elsevier Science. With permission.)