Biomedical Engineering Reference

In-Depth Information

the implant materials and surrounding osseous tissue, resulting in a strong interface between the

implant surface and bone [69]. Currently, plasma spraying is often used to coat titanium implants

with synthetic CaP fi lms and coatings. However, the CaP phases like carbonate apatite, which

resembles the composition and crystallinity of bone minerals, is diffi cult to be deposited because

of the extremely high processing temperatures [9,70]. Electrospraying has already been developed

as a novel coating technique to overcome the above-mentioned drawback. The experimental results

showed that the chemical properties of CaP coatings prepared using electrospraying technique

were strongly dependent on the chemical and physical properties of the precursor solution. Various

crystal phases and phase mixtures were formed, such as carbonate apatite, β-TCP, Mg-substituted

whitlockite, monetite, β/γ-pyrophosphate, and calcite, by varying the relative Ca/P solution ratio,

absolute precursor concentration, acidity of the precursor solution, and the type of Ca precursor

salt. The results showed that carbonate played an essential role in the chemical mechanism for the

formation of CaP coatings. Depending on the processing parameters of electrospraying, there were

three reactions for carbonate anions: (1) reaction with acidic phosphate groups, (2) incorporation

into apatitic CaP phases, and (3) reaction with excessive Ca

2

+

cations in case of phosphate-defi cient

precursor solutions.

Leeuwenburgh et al. also investigated the fabrication of CaP coatings with defi ned chemical

properties through electrospraying [71]. The relationships between various processing parameters

and the chemical properties of CaP coatings were studied to prepare the CaP coatings with tailored

chemical characteristics. The experimental results showed that the chemical properties of the CaP

coatings could be determined by the physical and chemical properties of solutions, as well as the

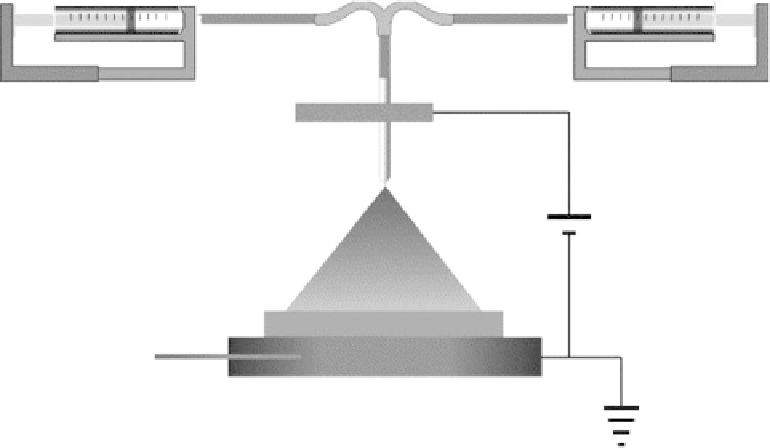

apparatus-related factors. Figure 11.20 shows a schematic diagram of the setup. Ca and P precursors

were prepared by dissolving Ca(NO

3

)

2

·4H

2

O or CaCl

2

·2H

2

O and H

3

PO

4

in butyl carbitol (C

8

H

18

O

3

)

or ethanol. A two-component nozzle with separate inlets for Ca and P precursor solutions was used

as a standard nozzle to avoid premature precipitation of precursors prior to the spraying generation.

By varying the processing parameters, the chemical properties of CaP coatings can be tailored to

have defi ned crystal phases ranging from the carbonate-free phases to carbonate-containing phases.

The experiment demonstrated that electrospraying was an appropriate technique to prepare coat-

ings with a large variety of chemical properties, which is especially suitable to the research focused

Liquid in

Nozzle

High-voltage supply

Aerosol spray

Substrate

Thermo

couple

Heating element

FIGURE 11.20

A diagram of the setup of the electrospraying for two solutions. (Reprinted from

Leeuwenburgh, S.C.G. et al.,

J. Eur. Ceram. Soc.

, 26, 487, 2006. © Elsevier Science. With permission.)