Biomedical Engineering Reference

In-Depth Information

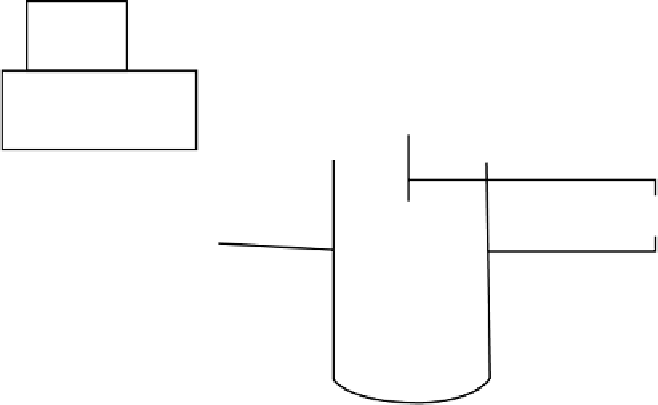

Stainless steel capillary

Copper

electrode

Infusion pump

Syringe

+++++

DC voltage

Copper

electrode

−−−−−

Power supply

0

−

3000 V

Collecting tube

FIGURE 11.14

A schematic representation of electrospraying equipment. (Reprinted from Reyderman, L.

and Stavchansky, S.,

Int. J. Pharm.

, 124, 75, 1995. © Elsevier Science. With permission.)

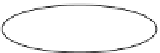

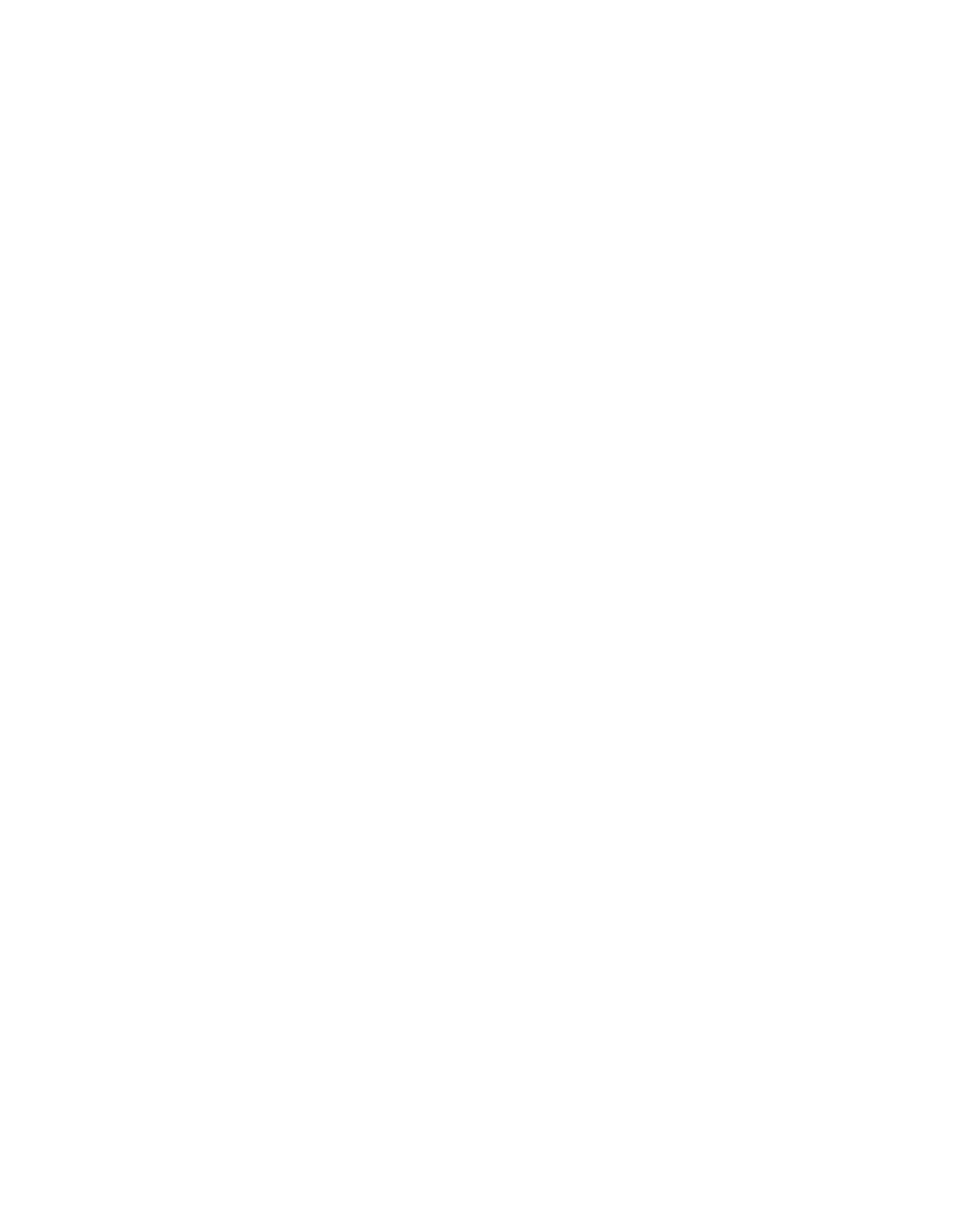

FIGURE 11.15

SEM of cholesterol microspheres prepared using electrospraying. (Reprinted from

Reyderman, L. and Stavchansky, S.,

Int. J. Pharm.

, 124, 75, 1995. © Elsevier Science. With permission.)

release formulation upon intramuscular or intradermal administration. A schematic diagram of the

apparatus used in the work is shown in Figure 11.14. The apparatus consisted of an infusion pump, a

glass syringe, a stainless steel capillary, and a power supply. The electrodes were positioned 0.2 cm

apart, one of them being at the tip of the capillary. A heating mantle controlled by a thermostat

was positioned around the syringe extending down to the capillary and upper electrode to main-

tain cholesterol in the molten state and to provide uniform fl ow for electrospraying cholesterol in a

molten state. SEM image revealed that the cholesterol microspheres prepared using a 3 kV voltage

source had a mixture of spherical particles of 150-250 µm, as shown in Figure 11.15. The experi-

ments demonstrated that electrospraying has another potential use in spraying a melt for producing

microspheres in a uniform size. However, considerations need to be placed on the thermal stability