Biomedical Engineering Reference

In-Depth Information

a

b

c

d

e

f

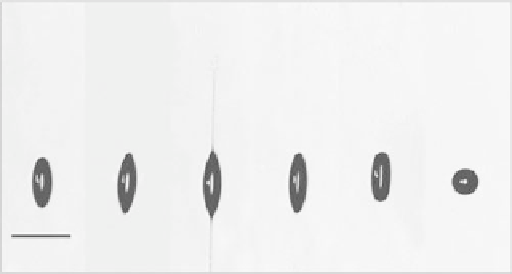

FIGURE 11.3

The disintegration process of levitated microdroplets. Scale bar—100 µm. (Reprinted from

Duft, D. et al.,

Nature

, 421, 128, 2003. © Nature Publishing Group. With permission.)

the current from the fl ow rate of the solution (

I

~

Q

1

/2

) when

D

1 (high conductivity and viscosity

liquids) and a fourth root dependence of the current from the fl ow rate (

I

~

Q

1

/4

) when

D

<

>

1 (low

conductivity and viscosity).

The multijet electrospraying mode has been observed by Shtern et al., Jaworek et al., and others

[31-35]. Only Jaworek et al. developed a stability map in the voltage-fl ow rate (

V

Q

) plane. Such

tremendous research studies have attracted the attention of many researchers who are interested

in the principles and potential application of electrospraying. In 1994, Cloupeau et al. described

and explained the different electrospraying patterns in terms of the electric potentials, the physi-

cal properties and the fl ow rate of the liquid, and the setup geometry of the system [36]. When the

physical properties of the solution and the parameters of the process are proper, a conical meniscus

is formed at the exit of the capillary to produce fi ne aerosol jets. In 2003, Duft et al. visualized the

Rayleigh droplet breakup using a high-speed camera [37]. Figure 11.3 shows high-speed imaging

of the disintegration of a levitated droplet charged to the Rayleigh limit. The results revealed that

an ethylene glycol droplet with an initial radius of 58 µm was captured using the camera, and the

droplet became unstable and emitted fi ne jets when it reached the size of 24 µm because of evapora-

tion. The liquid jets disintegrated into small droplets as the evaporation continued, and the inherent

instabilities of the jets ultimately led to its breakup into fi ne droplets.

-

11.2. 3 M

ECHANISMS

AND

M

ODES

OF

E

LECTROSPRAYING

It has been mentioned that electrospraying makes use of uniform electrohydrodynamic force rather

than inertial force to break liquid up into aerosols of fi ne droplets. When a high voltage is applied

over the droplet, the electric fi eld will induce free charge on the surface of the liquid droplets. The

free charge can be transported through two ways into the droplet [27,38]: either through conduction

due to the electric fi elds or through charge convection. This free charge consists of ions that are

accelerated toward the cone apex by the electric fi eld because of a tangential electric stress on the

free ions in the liquid. Therefore, the electric stress occurs on the surface of the droplets and pro-

duces a downward longitudinal force, transforming the shape of the droplet into a conical one. This

in turn results in a high charge density at the cone apex of the liquid jet. In a certain range of applied

voltage and fl ow rate—when the radial force exceeds the shear force—the liquid jet will break into

highly charged droplets with a narrow size distribution in a steady and special regime.

Theoretically, if a large potential is gradually applied to a capillary in an electrospraying process,

the dripping rate of the drops increases and the size of the liquid drops decreases. The jet is formed

by the stripping of the drop surface rather than by the pulling of the liquid from the bulk of the drop,

or the detachment of small droplets from the liquid apex [39]. At a certain potential and fl ow rate, the

droplets at the tip of the capillary can form different atomization modes, depending in part on the