Biomedical Engineering Reference

In-Depth Information

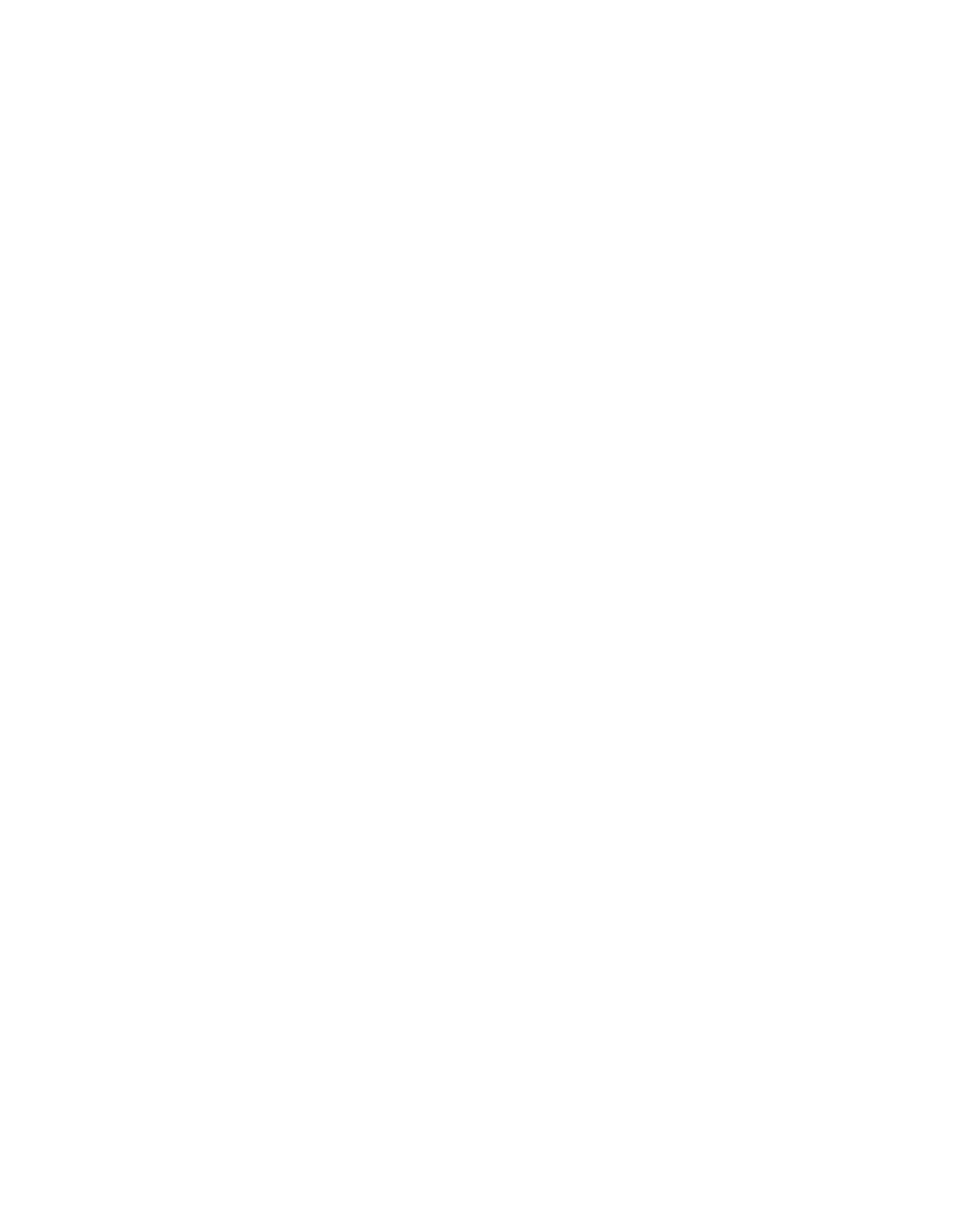

TABLE 10.1

Summary of Cell Adhesion on Different Polyion Films

Outermost

Layer

Alternating

Component

Surface Charge

at Neutral pH

Cell Types

Reference

PSS

PDDA

Negative

Hepatocyte, fi broblast

65

PAH

Negative

Smooth muscle cells

67

PAH

PSS

Positive

HUVEC

63

Gelatin

PDL

Negative

Endothelial cells

27

PDL

Fibronectin, laminin

Positive

Neuron

59

PGA

Positive

HUVEC

63

Hyaluronic acid

Positive

Fibroblast

64

Collagen

PAA

Negative

Muscle myoblast cells

35

Hyaluronic acid

Negative

Chondrosarcoma cells

68

Hyaluronic acid

PLL

Negative

Chondrosarcoma cells

66

CH

PSS

Positive

HUVEC

69

factors that control the cell adhesion behavior. Even for the same fi lm, different cells respond differ-

ently. For example, from Table 10.1, one can fi nd that hepatocytes, fi broblasts, and smooth muscle

cells (SMCs) adhered well on synthetic polyelectrolyte multilayered fi lms with an outermost layer

PSS, while HUVEC cells adhered well on a PAH layer. In contrast, poor endothelial cell adhesion

was found on a (PSS/PEI)

8

/PSS fi lm with the outermost layer PSS [27].

Polydimethylsiloxane (PDMS) (also called silicone rubber) is an interesting substrate for the

deposition of LbL thin fi lms and studying cell behavior on such a surface. First, it is used extensively

to study cell-substrate interactions because its mechanical properties are easily tuned in physiologi-

cally relevant ranges. Second, it can be used to make different medical devices (e.g., intraocular lens,

contact lens, catheters, etc.) because of its good biocompatibility and inertness. But the strong hydro-

phobicity of silicone rubber prevents cell adsorption

in vitro

, and it nonspecifi cally absorbs proteins

in vivo

with shortened lifetime. How to coat a thin and uniform hydrophilic fi lm on silicone is an

important, but not an easy step. Several surface modifi cation methods have already been reported,

including chemical immobilization [70], plasma treatment [71,72], and gelatin-glutaraldehyde cross-

linking [73]. Plasma treatment could deposit a high-quality thin fi lm, but application was limited to

surface areas that can be easily accessed. Tube-shaped vascular grafts are not suitable for plasma

deposition. In addition, the adsorption of matrix proteins to silicone rubber substrates through pas-

sive adsorption is relatively ineffi cient [74]. In an earlier attempt, we discovered that polyelectrolyte

fi lms can be used to modify silicone rubber surface hydrophobic property and the coating is stable

for endothelial cell adhesion and growth [27]. LbL self-assembly of polyelectrolyte was simple and

effi cient in surface modifi cation of silicone rubber. Without the help of any surface pretreatment,

polyelectrolytes can be directly applied onto such a surface through alternate coating of oppositely

charged polymers. Usually, highly charged polyelectrolytes PSS and PEI were used as precursor

layers in fi lm assembly; polypeptides were further coated to establish biocompatible coatings for

cell adhesion. Based on QCM quantifi cation, a PEI/PSS bilayer was about 2-3 nm, and a PDL/

gelatin bilayer has a thickness of 5 nm [27]. The thickness of the gelatin/PDL multilayers was linear

according to the number of layers. A fi lm composed of (PEI/PSS)

4

/(PDL/gelatin)

12

coated on a QCM

electrode was directly observed under SEM without metal coating (Figure 10.4a). The calculated

total fi lm thickness was 70 nm, which closely matched with the cross-section thickness of the fi lm in

this SEM image. When coating polyelectrolytes on silicone rubber, we found that using PSS as the

fi rst layer was more effi cient than a PEI layer. The reason is not clear, but we suspect hydrophobic

force between silicone rubber and PSS plays a major role here because silicone rubber is not charged.