Biomedical Engineering Reference

In-Depth Information

After the fi rst layer has been deposited, subsequent layers are deposited by moving the syringe up

along the

z

-axis by an amount corresponding to the height of each layer. To avoid collapse of over-

hanging structures during the fabrication process, a water-soluble polymeric spacer of about 10-20

µm is deposited between layers. Different layers can be built from different polymers in different

patterns, adding to the fl exibility of the technique. Once the microfabrication steps are completed, the

scaffolds are rinsed with water to remove the polymeric spacer for creating interspaces where the cells

can penetrate and adhere to initiate the proliferation process. Typically it takes about 30 s to realize

a 2-D layer of 1 cm

1 cm. In the case of 3-D scaffolds, the postprocessing phase requires about

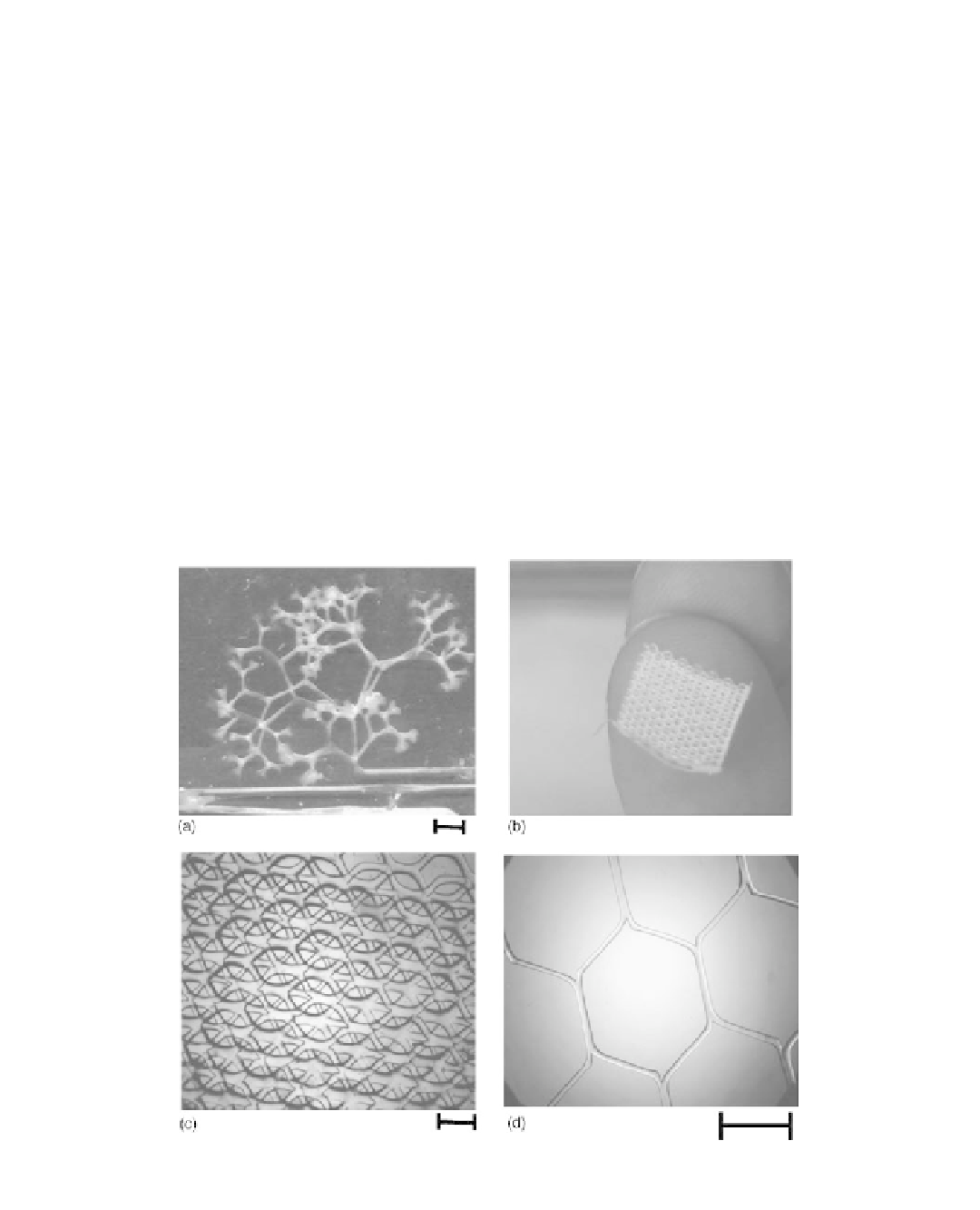

6-24 h of rinsing. Examples of the scaffolds realized with PAM are shown in Figure 4.4.

The PAM method has the highest resolution among the RP methods and has been adapted by

several research groups [5]. Its main drawbacks are the low vertical dimensions (due to the high

resolution) and as a result a fairly low RTM ratio, which implies that thick constructs take over an

hour to fabricate. Furthermore, the incorporation of the small particles such as hydroxyapatite and

nanotubes requires a capillary needle with a larger exit diameter to avoid clogging of the syringe,

so precluding high resolutions.

×

4.5.2 F

USED

D

EPOSITION

M

ODELING

FDM is an RP process that extrudes polymeric materials in molten form through the use of a heated

deposition head developed at the National University of Singapore (NUS). The system is composed

of a microcontrolled mechanical arm, which moves in the horizontal plane on which the extrusion

head is positioned. A fi lament of polymer is drawn into the head through the use of rollers, where

FIGURE 4.4

Typical (a) fractal (scale bar 1 mm), (b) 3-D hexagonal, (c) 3-D hexagonal detail (scale bar

500 µm), and (d) high-resolution 2-D hexagonal (scale bar 500 µm) scaffolds of PLGA obtained by PAM.