Biomedical Engineering Reference

In-Depth Information

4.5.1 P

RESSURE

-A

SSISTED

M

ICROSYRINGE

S

YSTEM

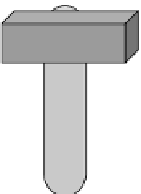

The pressure-assisted microsyringe (PAM) technique, developed at the Interdepartmental Research

Center “E. Piaggio” at the University of Pisa, is based on the use of a microsyringe that allows the

deposition of a wide range of polymers, as well as hydrogels [12]. The system consists of a stain-

less-steel syringe with a 10-20 μm glass capillary needle, as shown in Figure 4.3. A solution of the

polymer, in a volatile solvent, is placed inside the syringe and expelled from the tip by the application

of fi ltered, compressed air. The syringe is mounted on the

z

-axis of a three-axis micropositioning

system, which was designed and built in-house. A supporting substrate, usually glass, is placed on

the two horizontal motors and is moved relative to the syringe. The control software is developed

in C

(a programming language) with a user-friendly graphical interface and allows a wide range

of patterns with a well-defi ned geometry to be designed and deposited. Within horizontal plane, the

resolution of PAM-fabricated parts is 5-600 μm. This resolution depends on the pressure applied

to the syringe, the viscosity of the solution, the motor speed, and the dimensions of the syringe tip.

++

Compressed filtered air

PC

Pressure regulator

Micropositioner

z

Glass needle tip

y

x

FIGURE 4.3

Block diagram of the pressure-assisted microfabrication (PAM) system. The inset illustrates

the capillary needle with an inner diameter of 20 µm.