Biomedical Engineering Reference

In-Depth Information

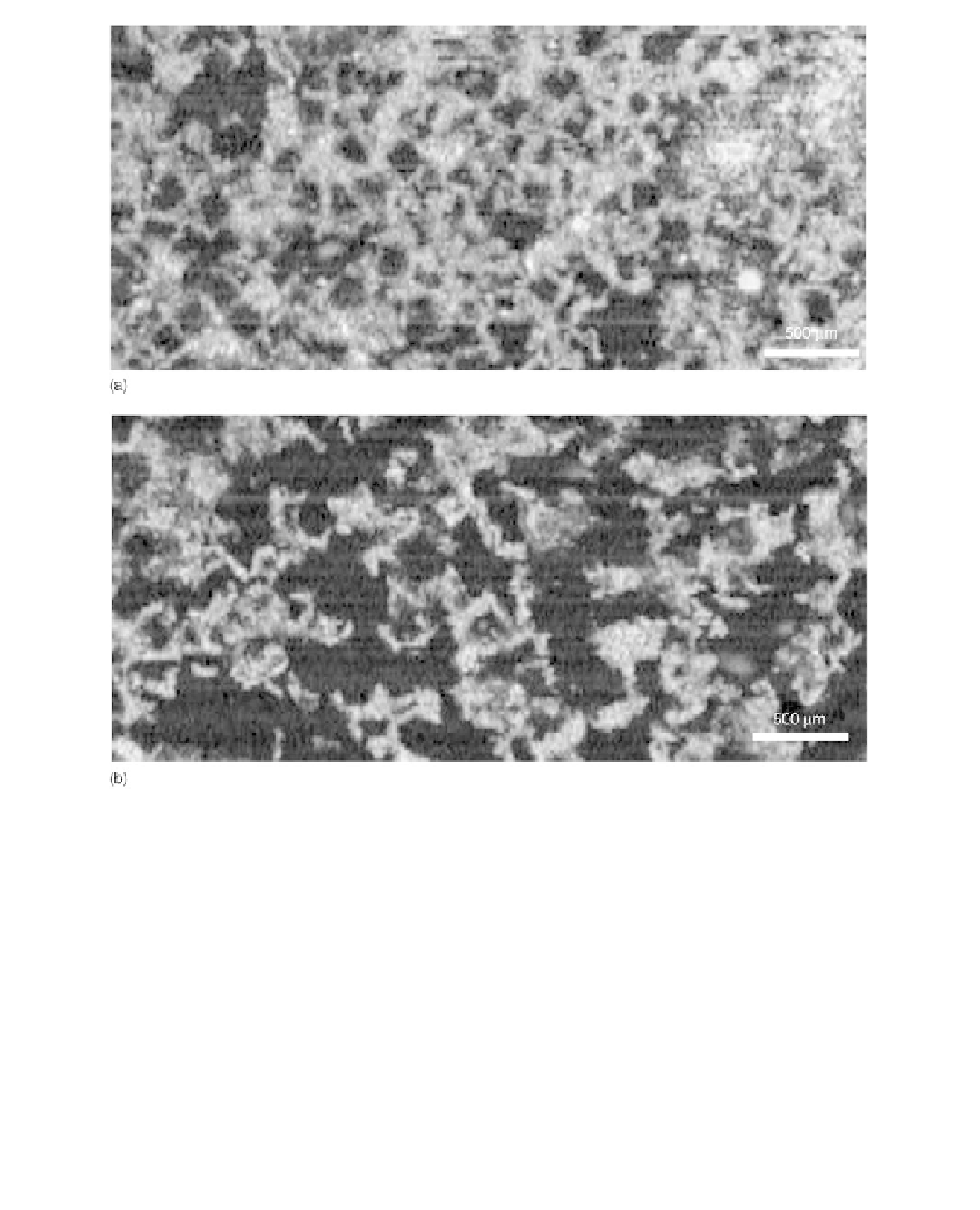

FIGURE 3.8

Top view OCT images of porous PLLA scaffolds generated by (a) single porogen and (b) dual

porogen. The pore size ranged from 106 to 255 µm. The concentration of the second porogen, that is, naph-

thalene, was 20%.

trapped naphthalene can be removed either by slow sublimation or dissolution in organic solvent. We

utilized THF as the solvent to remove naphthalene because THF has low infl uence on PLLA. With

such sequential pore generation, we can control the pore interconnectivity. In fact, the pores gener-

ated by naphthalene were much smaller than those generated by NaCl because when naphthalene was

mixed with the PLLA solution, it was a fi ne powder. It is the presence of these fi ne pores on the wall of

the larger pores that enhances the scaffold pore interconnection, allowing a better exchange of nutri-

ents and gas. The unique feature of this technique is that it neither requires complicated facilities nor

comprehensive processing methods, and the process can maintain a high productivity.

The manufacturing of fi brous scaffolds is another effi cient way to generate highly intercon-

nected porous scaffolds. With proper precipitation solvent, wet-spinning method can produce scaf-

folds with different porosity and fi ber diameter. Interestingly, it has been found that with the change

of porosity or diameter of the fi brous chitosan scaffold, it is possible to tailor the degradation rate of