Information Technology Reference

In-Depth Information

Target

Target

Target

Target

Target

Target

Target

Target

Target

Target

Target

Target

Target

Target

Target

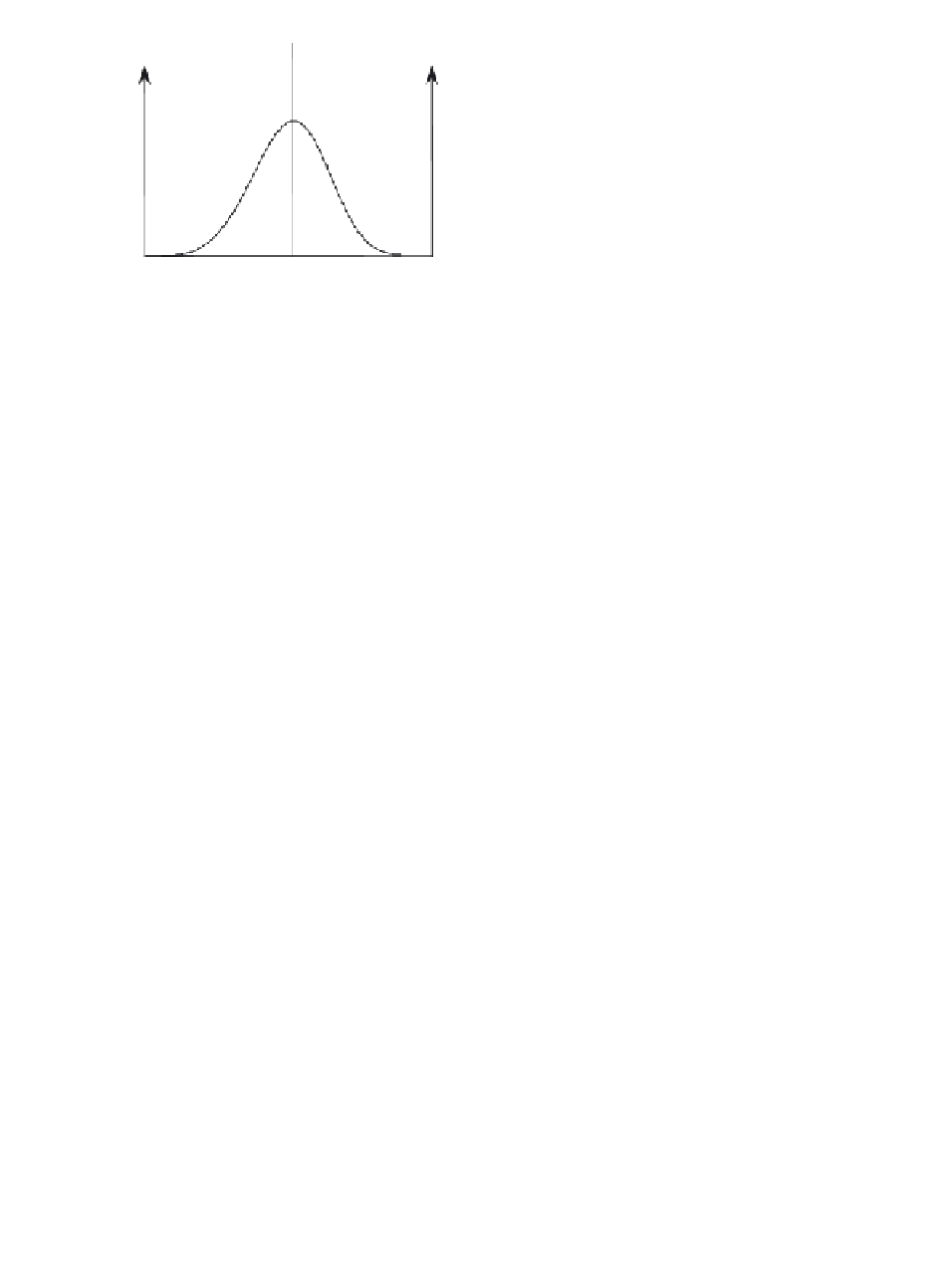

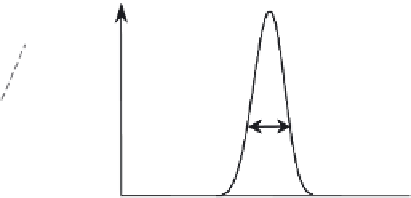

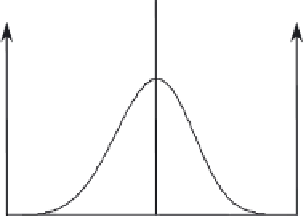

f(FR), pdf

f(FR), pdf

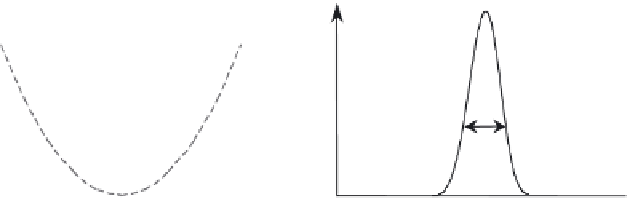

QLF(FR)

QLF(FR)

f(FR), pdf

f(FR), pdf

QLF(FR)

QLF(FR)

2

2

1

1

σ

σ

σ

σ

σ

σ

σ

σ

σ

σ

σ

σ

σ

σ

σ

μ

μ

μ

μ

FR

= T

μ

μ

FR

= T

FR

FR

FR

FR

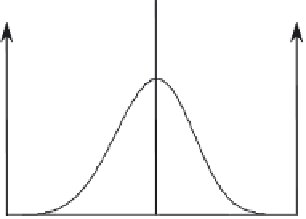

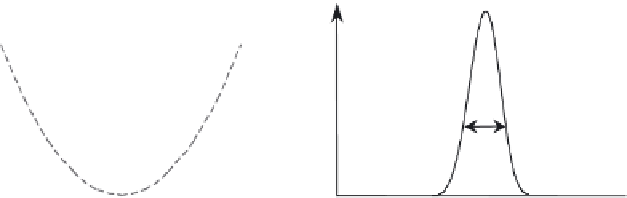

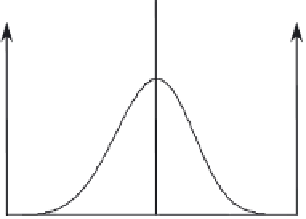

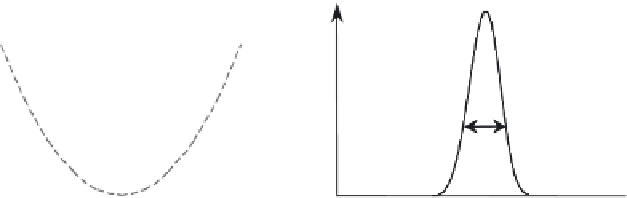

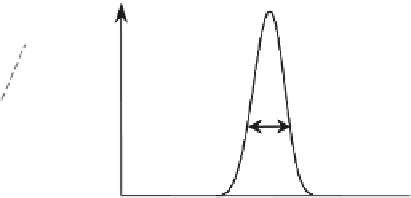

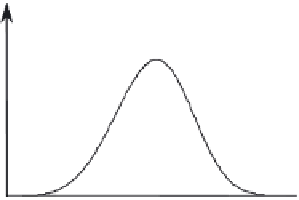

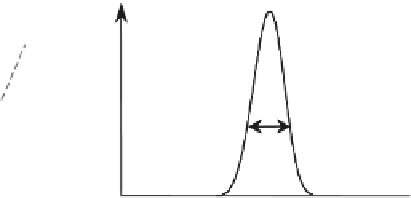

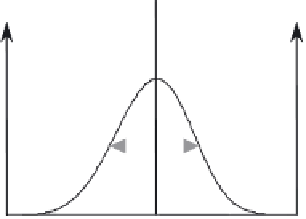

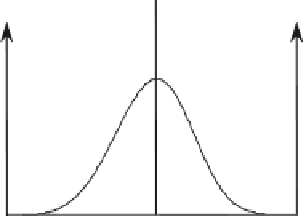

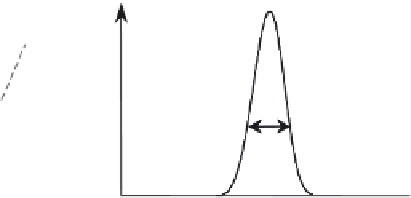

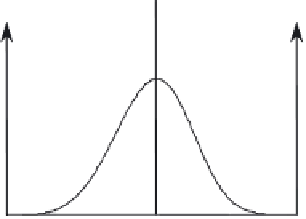

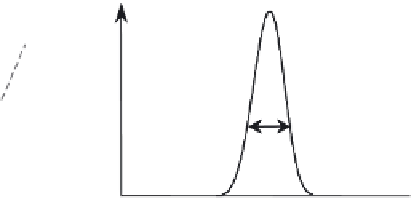

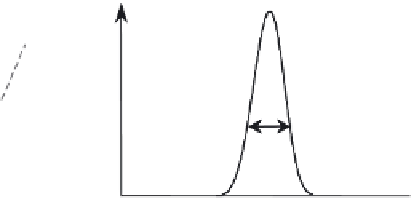

FIGURE 18.4

The quality loss function scenarios of figure 18.3.

of complexity based on axiom 2.

5

Setting 1 (DP

*

) also will produce a lower quality

loss similar to the scenario on the right of Figure 18.4. In other words, the design

produced by setting 1 (DP

*

) is more robust than that produced by setting 2. Setting 1

(DP

*

) robustness is evident in the amount of transferred variation through the transfer

function to the FR response of Figure 18.2 and the flatter quadratic quality loss func-

tion in Figure 18.3. When the distance between the specification limits is six times

the standard deviation (6

σ

FR

), a Six Sigma level optimized FR is achieved. When

all design FRs are released at this level, a Six Sigma design is obtained.

The important contribution of robust design is the systematic inclusion into ex-

perimental design of noise variables, that is, the variables over which the designer

has little or no control. A distinction also is made between internal noise (such as

dimensional variation in aperture, the size and quality of the sensor, the gain, and

the exposure time), and environmental noise, which the DFSS team cannot control

(e.g., humidity and temperature). The robust design's objective is to suppress, as far

as possible, the effect of noise by exploring the levels of the factors to determine

their potential for making the software insensitive to these sources of variation in the

respective responses of interest (e.g., FRs).

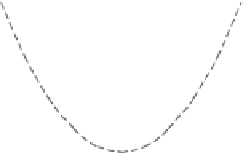

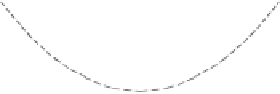

The noise factors affect the FRs at different segments in the life cycle. As a result,

they can cause a dramatic reduction in product reliability, as indicated by the failure

rate. The bath tub curve in Figure 18.5 implies that robustness can be defined as

reliability throughout time. Reliability is defined as the probability that the design

will perform as intended (i.e., deliver the FRs to satisfy the customer attributes (CAs)

[(Figure 13.1)], throughout a specified time period when operated under some stated

conditions). The random failure rate of the DPs that characterizes most of the life is

the performance of the design subject with external noise. Notice that the coupling

vulnerability contributes to unreliability of the design in customer hands. Therefore,

a product is said to be robust (and, therefore, reliable) when it is insensitive to the

effect of noise factors, even though the sources themselves have not been eliminated.

5

See Chapter 13.

Search WWH ::

Custom Search