Information Technology Reference

In-Depth Information

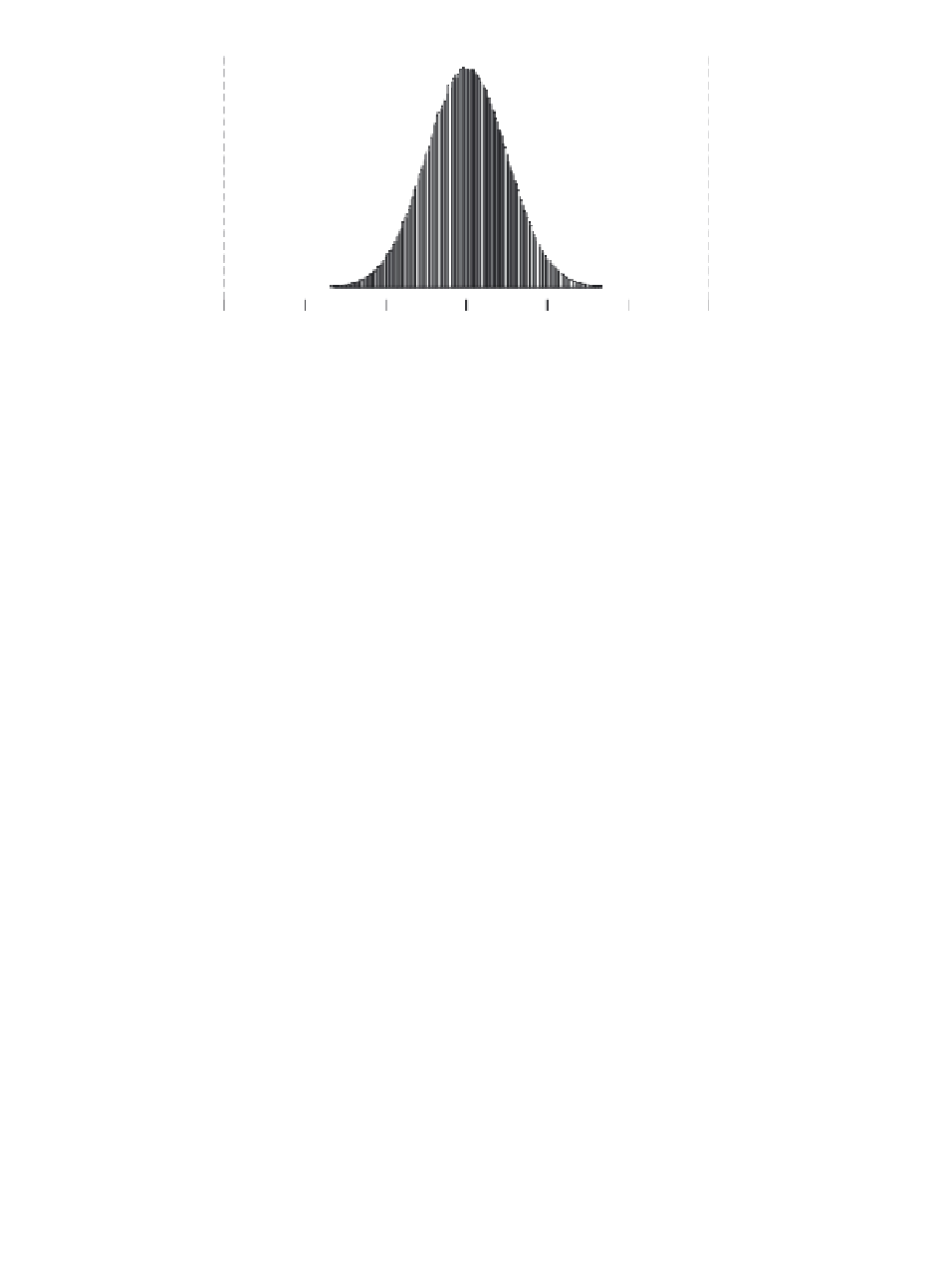

LSL

USL

-6

σ

+6

σ

-6

-4

-2

0

2

4

6

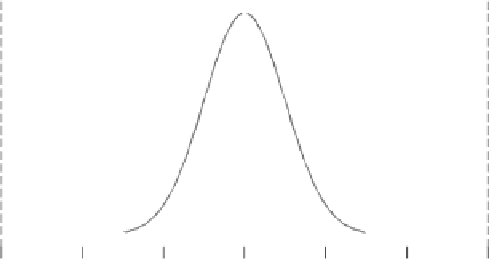

FIGURE 7.12

Six Sigma capable process (short term).

When a process spread is greater than the specification spread, the process is

incapable of meeting the specifications and a significant amount of the output will

fall outside of the specification limit and will yield unacceptable performance. The

sigma level is also know as the

Z

value (assuming normal distribution) and for a

certain CTQ is given by

USL

−

mean

or

mean

−

LSL

Z

=

(7.1)

σ

σ

where USL is the upper specification limit and LSL is the lower specification limit.

7.7.1

Motorola's Six Sigma Quality

In 1986, the Motorola Corporation won the Malcolm Baldrige National Quality

Award. Motorola based its success in quality on its Six Sigma program. The goal

of the program was to reduce the variation in every process such that a spread of

12

on each side of the average) fits within the process specification limits (see

Figure 7.12).

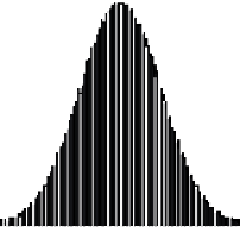

Motorola accounted for the process average to shift side to side over time. In

this situation, one side shrinks to a 4.5

σ

(6

σ

(see

Figure 7.13). This shift accounts for 3.4 parts per million (ppm) on the small gap and

a fraction of parts per billion on the large gap. So over the long term, a 6

σ

gap, and the other side grows to 7.5

σ

σ

process

will generate only 3.4 ppm defect.

To achieve Six Sigma capability, it is desirable to have the process average centered

within the specification window and to have the process spread approximately one

half of the specification window.

There are two approaches to accomplish Six Sigma levels of performance . When

dealing with an existing process, there is the process improvement method also known

Search WWH ::

Custom Search